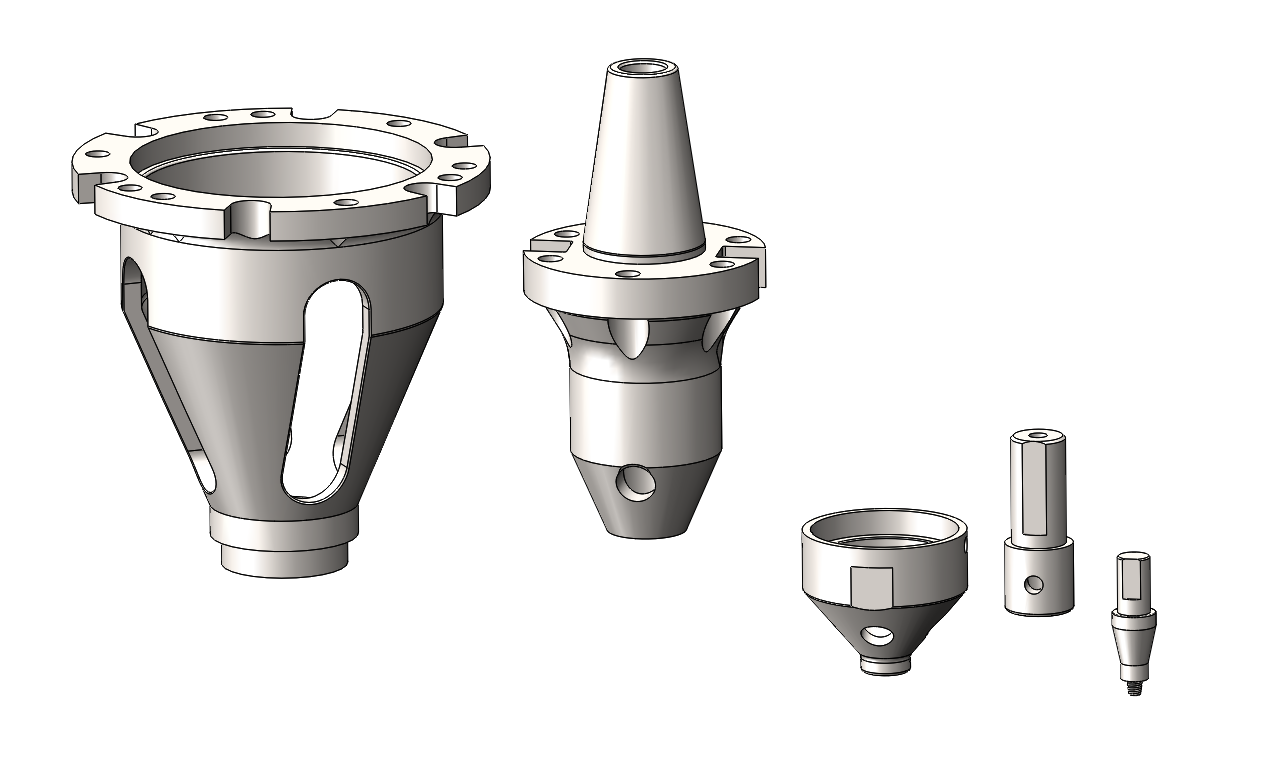

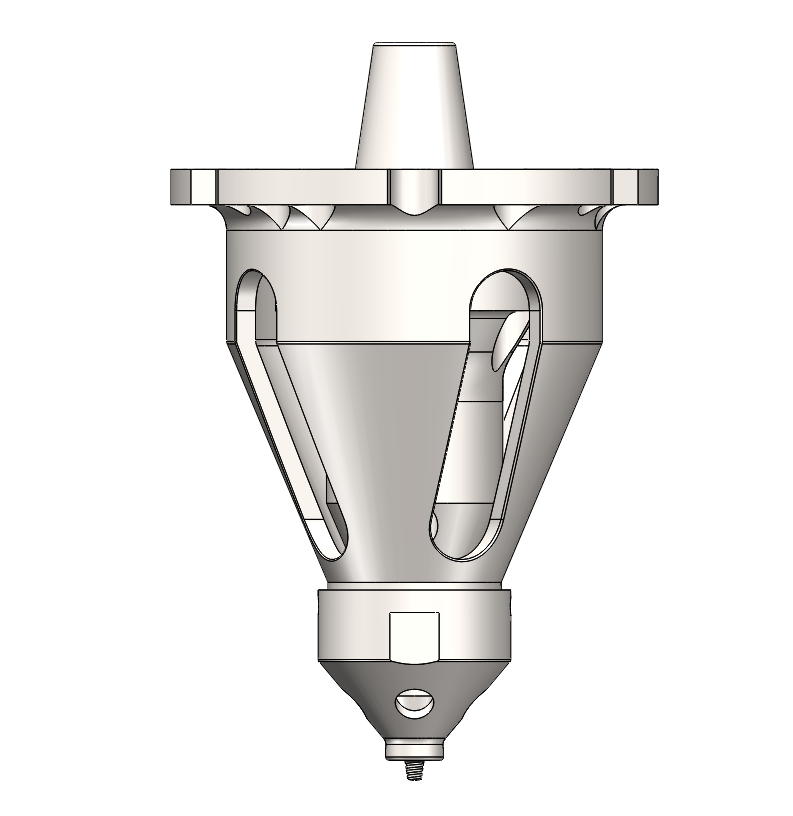

Stationary shoulder friction stir welding (SSFSW) is a new friction stir welding technology. Through using specific shape of stationary shoulder, SSFSW can solve any angle of plate welding problem (such as T-type weld). In the structure of SSFSW tool, the shoulder is separated from the pin. When welding, the pin rotates alone, and the shoulder slides relatively on the surface of the material. Compared with the traditional friction stir welding process, the stationary shoulder friction stir welding can reduce the heat input during welding and obtain a uniform thermal gradient in the thickness direction, thereby improving the surface quality of the joint. The stationary shoulder friction stir process is suitable for welding aluminum alloy thick plates, fillet welds, titanium alloys and other materials with low heat transfer rates.

AEE has researched the plate welding technology of many kinds of angle, such as 90°, 180°, 202° and so on.

Type of FSW tool | Apply material | Welding thickness/mm | Technology characteristic | Application |

Stationary shoulder FSW tool | (1) Common aluminum alloy (4XXX、5XXX、6XXX) | 1.0-110.0 | 1. Any angle of plate welding can be achieved (such as 90°,180°,202° and so on); 2. Low heat inputting and small deformation; 3. Without flash during welding process. | Rail trains, aerospace, new energy auto parts (motor shells, water-cooled plates, battery trays, car wheels, etc.) |

(2)High-strength aluminum alloy | ||||

(3)Cast aluminum alloy | ||||

(4)Magnesium alloy | 1.0-20.0 | |||

(5)Titanium alloy | 1.0-15.0 | |||

(6)Copper alloy | 1.0-20.0 | |||

(7)Steel alloy | 1.0-10.0 |