With years of know-how as a technology and system partner, we offer a comprehensive turnkey packages and support you from the product idea to series production.

◢ Welding depth 1-8 mm

◢ Welding rate 1500 mm/min

◢ Cycle time 6 JPH

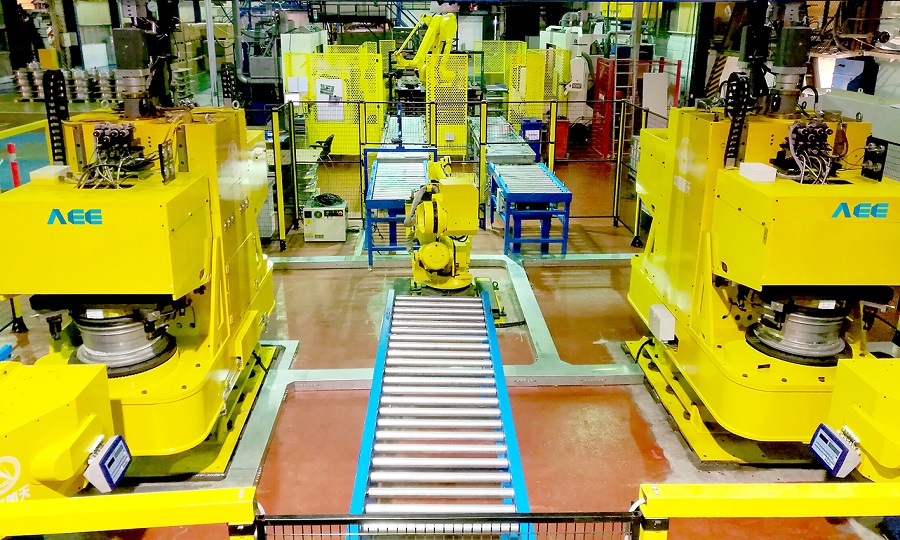

The full automation FSW production line for aluminum alloy wheel hub customized for European customer is integrated with QR code scanning, robot automatic loading and unloading, criterion automatic identification & positioning, wheel disc & rim automatic clamping, constant pressure welding functions, it’s suitable for circumferential welding of aluminum automobile hub and cylinder component.

◢ Welding depth 1.2-10 mm for wheels diameter of 17-22 in

◢ Welding rate up to 2,500 mm/min, 6,000 rpm of spindle

◢ Cycle time 45 JPH

◢ Retractable FSW tool without keyhole Traceability

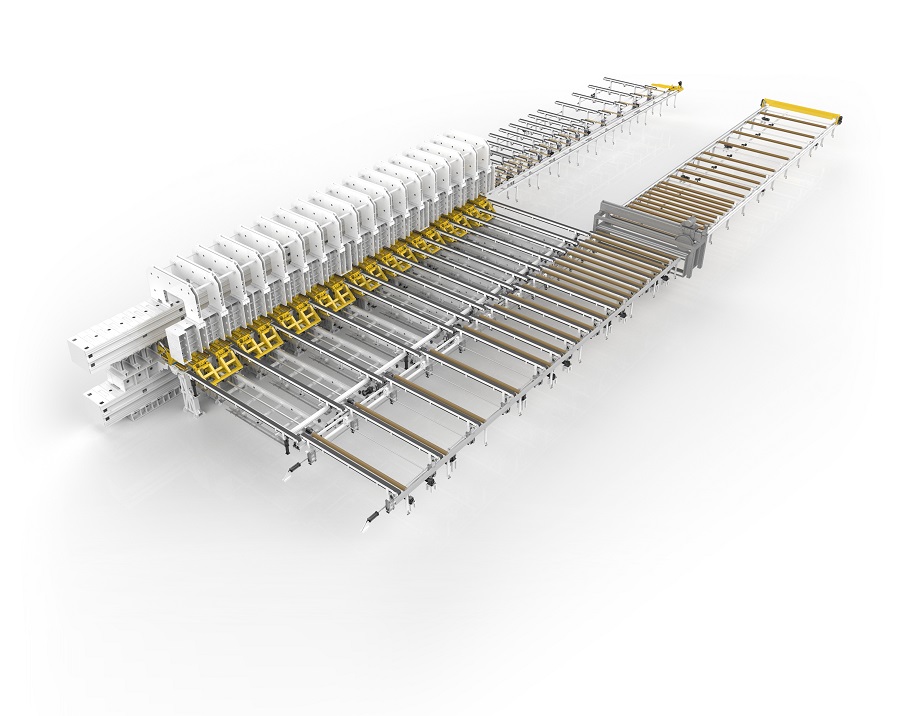

Case 3-- Fully automatic FSW Production Line for Long Straight Profiles

The double-side FSW production line for long and straight aluminum profile welding, which has been exported to European company realizes the full automatic process from welds tracking, feeding, clamping, discharging to cutting that is suitable for long and straight welding of wide-width long aluminum profiles in fields of rail transit, shipping, etc.

◢ Welding depth 1.2~16 mm

◢ Max. length up to 18,000 mm

◢ Max. width up to 3,500 mm

◢ Simultaneous welding with double sided head Water cooling FSW tool

◢ Fully automatic process including loading, clamping, seam pre-inspection, FSW, unloading, cutting etc.

◢ With laser tracking, force control and other functions