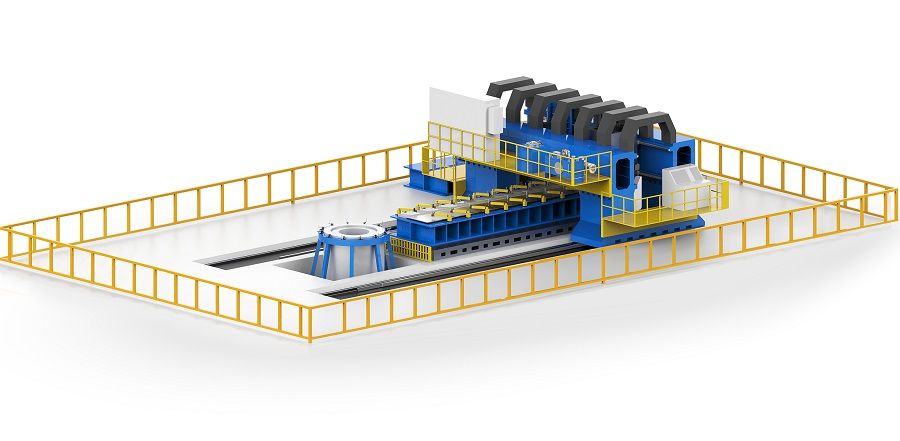

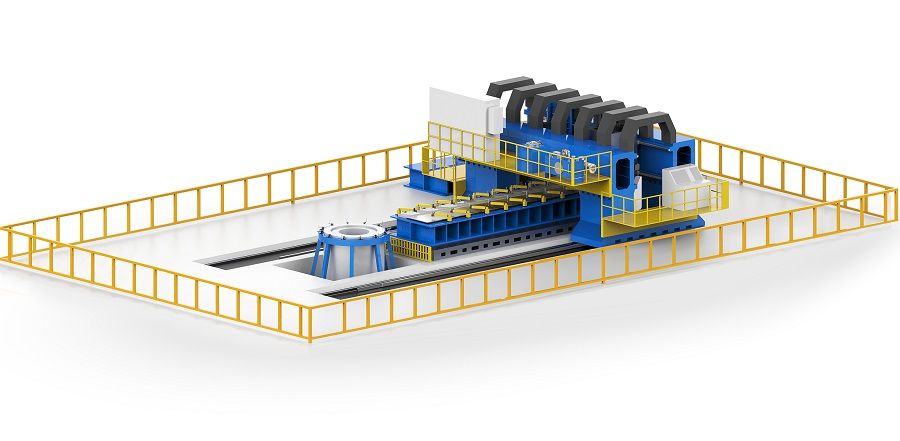

The FSW machine with double beam and light & heavy-load integrated head can realize single-side welding depth of 100 mm of aluminum alloy and 35 mm single-side welding depth of copper alloy, meets the application needs of friction stir welding for extra depths aluminum alloy.

Machine Model | AEE-FSW100x100/2 | ||

Working Table(W×L) | (mm) | 3000× 8000 | |

Machine width×depth×height | (mm) | 10000×4200×500 | |

Machine weight | (kg) | 20000 | |

Welding thickness | (mm) | 100 | |

Stroke | X axis | (mm) | 10000 |

Y axis | (mm) | 4200 | |

Z axis | (mm) | 500 | |

C axis | ( 。) | N×360 | |

B axis | ( 。) | 0-5 | |

Feed rate | X axis | (m/min) | 10 |

Y axis | (m/min) | 3 | |

Z axis | (m/min) | 1 | |

C axis | (r/min) | 5 | |

Axis accuracy | Positioning X/Y/Z | (mm) | 0.05 |

Repeatability X/Y/Z | (mm) | 0.03 | |

Spindle parameters | Spindle Speed | (rpm) | 1000 |

Spindle Torque | (NM) | 872 | |

Spindle power | (KW) | 105 | |

Force parameters | Max. force in Z-axis | (KN) | 200 |

Max. force in X-axis | (KN) | 100 | |

This FSW machine has good rigidity, strong bearing capacity, and high-precision and stable welding process. The machine is equipped with a high-quality spindle with a hydraulic cooling system. It can meet the full coverage needs from thin sheet to thick plates and realize FSW of spatial 3D thick plate.

As an expert in intelligent friction stir welding solutions, AEE focuses on developing top-notch FSW machines and processes, understanding cutting-edge technologies and trends, and tackling innovative technologies to provide comprehensive welding module manufacturing solutions for industry clients.

To know more information about Heavy head Friction stir Welding Machine, welcome to surf in the website: https://a-fsw.com/