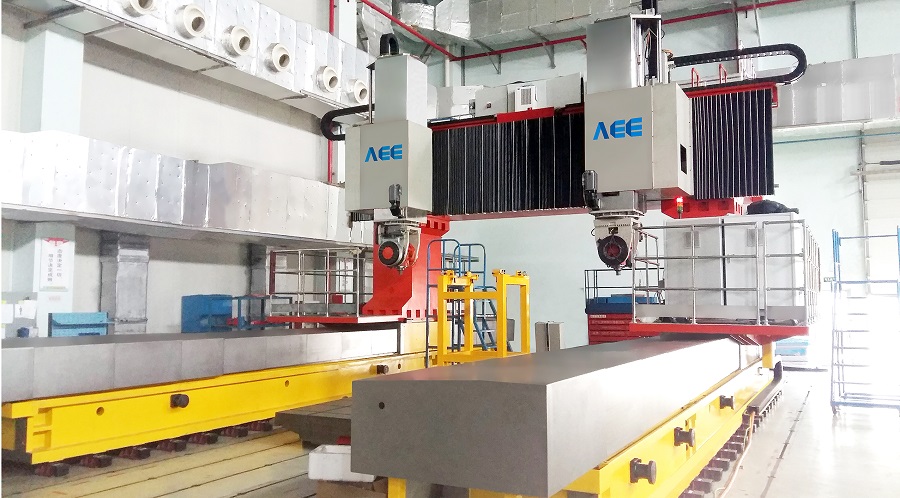

Dual head FSW machine

The domestic first dynamic gantry-type FSW machine with double beam and light & heavy-load integrated head can realize single-side welding thickness of 100mm of aluminum alloy and 35mm single-side welding thickness of copper alloy, meets the application needs of friction stir welding for extra thickness aluminum alloy.

Technical Specifications

Model | AEE-FSW100×100/3H | |

Welding Thickness | (mm) | Single-side 100, double-side 190 |

Working Table(W*L) | (mm) | 8000*3000 |

Gantry Net Height | (mm) | 644-1144 |

Gantry Net Width | (mm) | 4500 |

Spindle Maximum Speed | (rpm) | 1500 |

Machine Outline Dimension | (mm) | 19000*10800*4800 |

Highlights

l High rigid structure and heavy load capacity

l High welding efficiency

l High-quality seams

l Reliable welding quality of materials under low torque

l Automated tool changing system

l Force/ Position/ Torque / Temperature control

l Safety guarding system

l Remote assistance

l Data acquisition, visual identity, laser tracking and weld monitoring systems

Features

l Double beam double gantry structure is adopted, with big rigidity and load capacity.

l The beam and machine bed adopts high strength casting, with double gear motor anti-backlash structure, improving the overall welding stability.

l The integration of light-load and heavy-load head is used to meet the full coverage needs from thin plate to thick plate.

l The heavy-load head adopts parallel mechanism, which can realize friction stir welding of spatial 3D thick plate, and the space position is accurate.

Application

Rail transit; national defense industry; automobile industry

Single-side Dual head FSW equipment

Dual-side Dual head FSW equipment