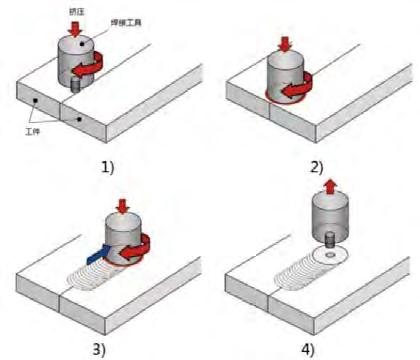

What is friction stir welding (FSW)? - Process and Applications

Mechanical Properties and Microstructure

The mechanical properties of friction stir welded aluminium alloys have been proven better than those found with other welding processes, such as arc welding.

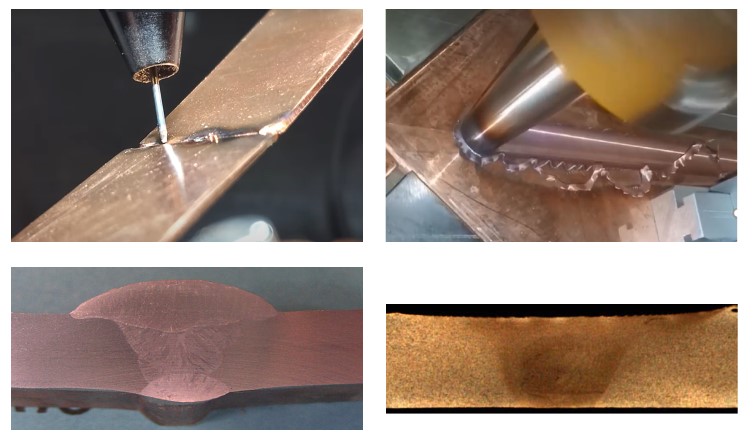

With regard to the mechanical properties of FSW, this process typically has three main microstructural regions; a weld nugget, a thermo-mechanically affected zone (TMAZ) and a heat affected zone (HAZ).

While both the weld nugget and the TMAZ are ‘thermo mechanically affected zones,’ they are considered separately when it comes to the micro-structural features. This is because the weld nugget experiences dynamic recrystallization while the TMAZ does not. However, the exact composition and extent of the microstructural composition in these zones depends upon the material and processing conditions. These can, for example, alter depending on factors such as welding parameters and the design of the FSW tool used.

Application

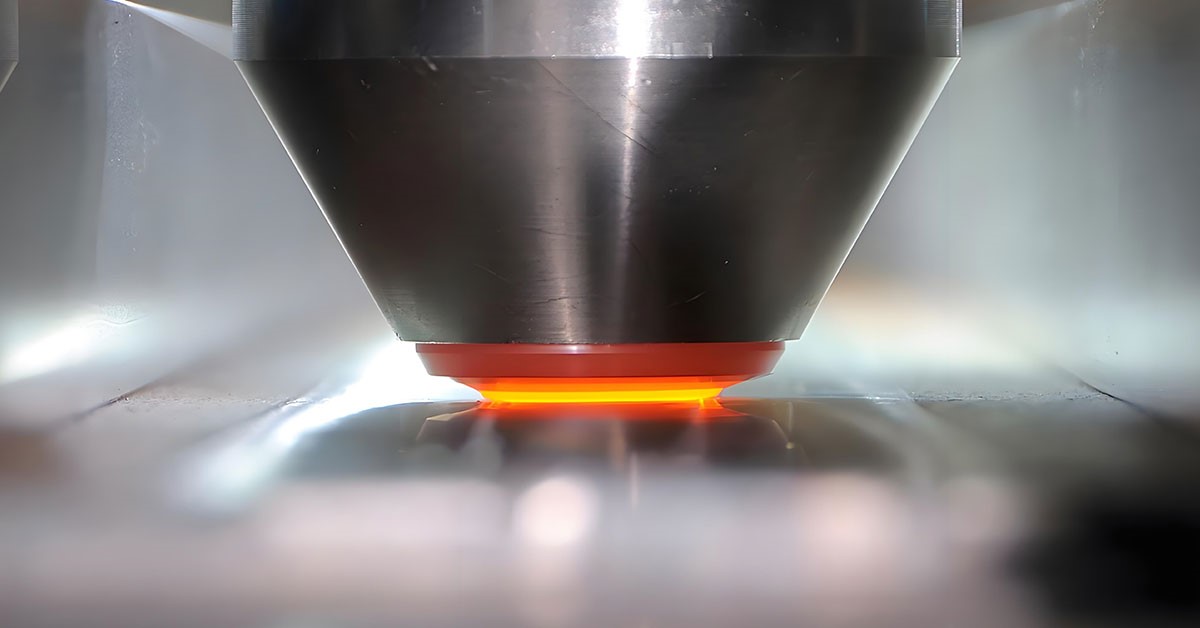

The process is primarily used in industry to join aluminium alloys of all grades, whether cast, rolled or extruded. FSW has been shown to weld aluminium alloy butt joints with a thickness of between 0.3mm and 75mm in a single pass, depending on the alloy grade and capability of the FSW machine.

Other materials that have been joined with FSW include magnesium, titanium, copper, nickel and steel alloys, while plastics and metal matrix composites (MMC) have also been explored. This process has also been shown to be able to join dissimilar combinations of these materials including aluminium to steel.

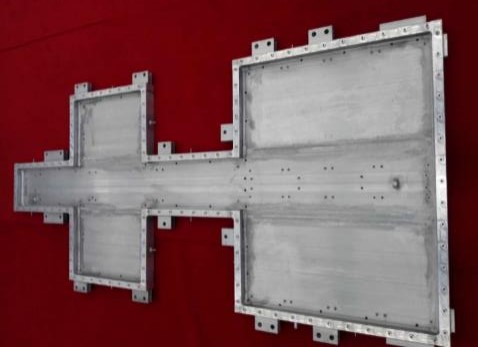

FSW has been used for a variety of applications across industries ranging from aerospace to shipbuilding and rail to electronics, including EV battery trays.

What are the Advantages?

Friction stir welding offers a number of advantages over conventional arc welding processes. These include:

As a solid state welding process, FSW is a largely defect free joining method with no hot cracking, porosity or solidification cracks.Due to the lower temperatures there is a reduction in shrinkage and distortion in the material being joined. FSW is environmentally friendly as it produces no fume, spatter, or UV radiation. Uses machine tool technology, making the process easy to automate, highly repeatable and reducing need for skilled welders.

What does AEE offer?

AEE has the R&D and system integration ability of mechanical, electricity and liquid integration equipment, and provides welding and technical service as well.AEE has achieved industrialization of friction stir welding technology worldwide.

AEE has an overall comprehensive strength in the research and development of special intelligent machine, non-standard design and manufacturing capabilities, and automation system control development capabilities. AEE insist on constant innovation, and focuses on the needs of customers, targeting to be one of the global most significant suppliers of friction stir welding machine and providing customers with system integration and technical service with medium and high quality.

About Friction stir welding related products,more information can be found on the website: https://a-fsw.com/