Analysis of microstructure and mechanical properties of friction stir welded joint of Cu/Al dissimilar materials

《Electric Welding Machine》 October 2020, Vol. 50 No. 10

Analysis of microstructure and mechanical properties of friction stir welded joint of Cu/Al dissimilar materials

XU Meng, LI Wenxiao, XU Xiaoxia, PEI Pengfei, YAN Junfu, FAN Meihua (Aerospace Engineering Equipment (Suzhou) Co., Ltd., Suzhou 215200, China). pp 1-6

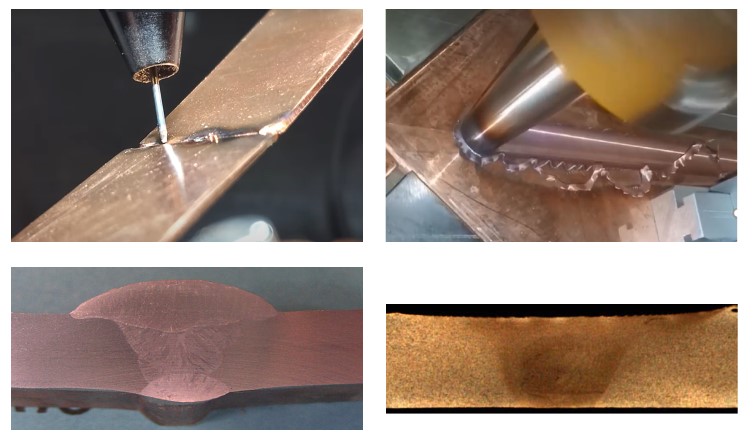

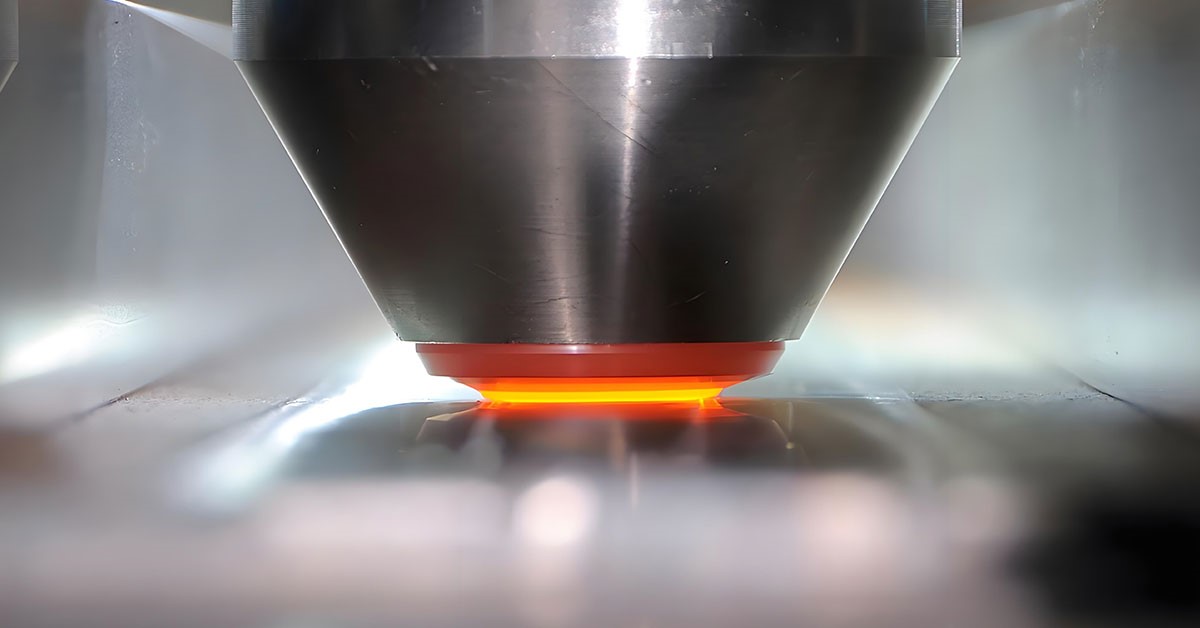

Abstract: The butt joints of dissimilar materials (1060-O aluminum alloy, T2 copper) were welded by two kinds of friction stir welding. The effects of two different rotation speeds on the microstructure and mechanical properties of the joint were studied by means of metallographic observation, micro-hardness test, tensile test and SEM fracture scanning, and the microstructure of fracture was also analyzed. The results show that the cross section macro-morphoee4logy of the dissimilar FSW joint is characterized by the interpenetrating and mixing of the two base metals. The copper alloy particles are dispersed in the aluminum alloy matrix in the nugget zone (NZ), and the aluminum copper intermetallic compound (IMC) forms at the interface of the two metals in the NZ. The embedded layer depth of copper in the NZ of higher-speed aluminum copper welding joint is larger, the microstructure of the TMAZ on the aluminum side is stirred more violently, and the grain are elongated and twisted more obviously. The mechanical properties of high-speed joints are better than those of lower-speed joints, which have higher joint hardness and tensile properties.

Key words: friction stir welding; aluminum copper welding; rotation speed; mechanical properties