AEE FSW technology has successfully addressed the welding challenges of copper alloy bus-bar in mass production

Recently, AEE has triumphantly tackled the challenge of welding copper alloy bus-bars for its clients, leveraging friction stir welding (FSW) technology.

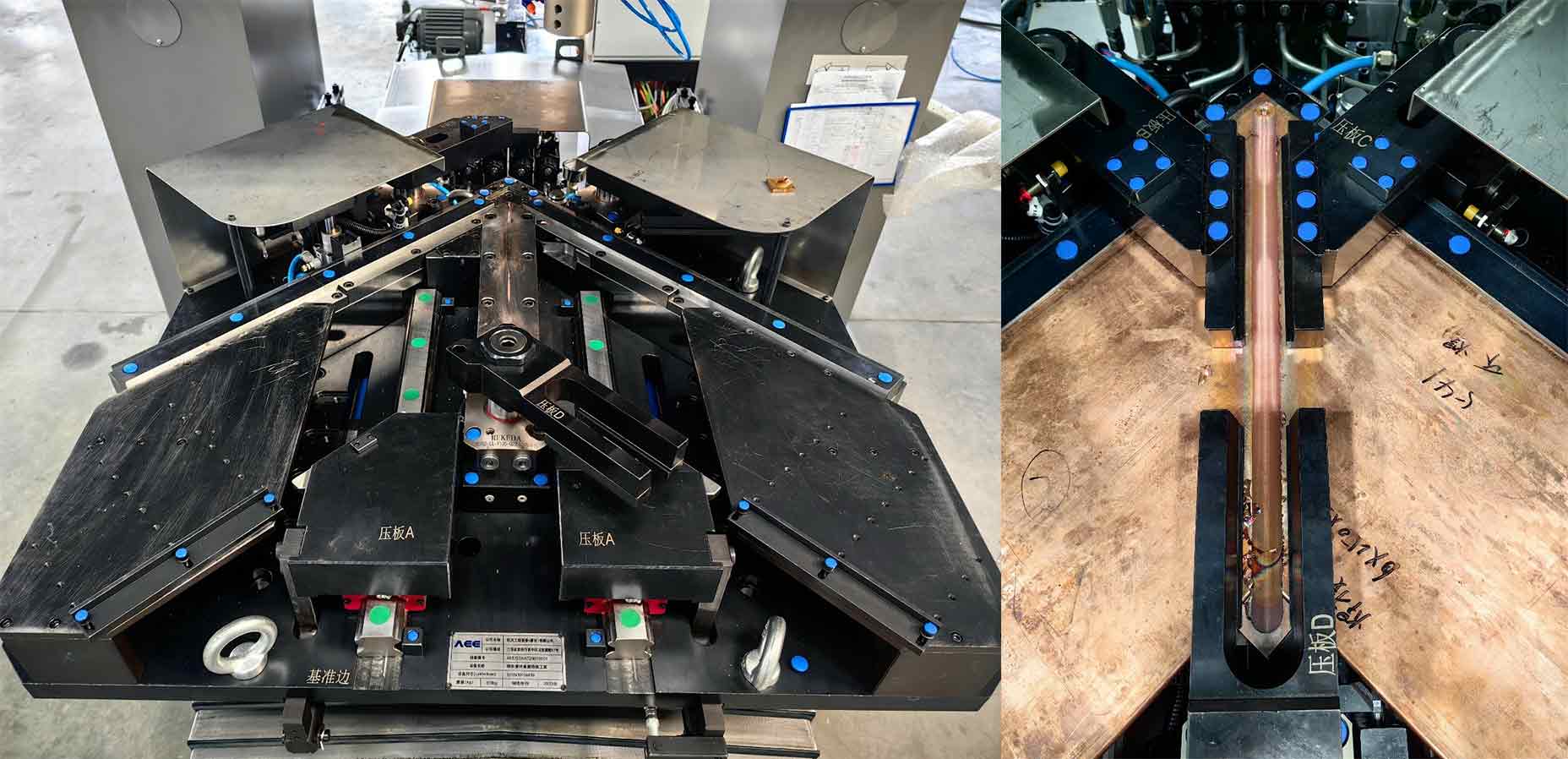

We provided a turnkey solution, encompassing FSW equipment, welding fixtures, and optimized welding processes, enabling clients to embark on mass production of bus-bar. This not only elevated welding efficiency and product quality but also significantly reduced production costs.

Copper and its alloys, renowned for their exceptional electrical and thermal conductivity, find ubiquitous applications across electronics, electrical engineering, energy & petroleum, transportation, and light industries.

Copper bus-bar, as heavy-duty current conductors, are essential in high- and low-voltage electrical appliances, switch contacts, power distribution equipment, bus ducts, and colossal current electrolytic processes such as metal smelting, electrochemical plating, and caustic soda production.

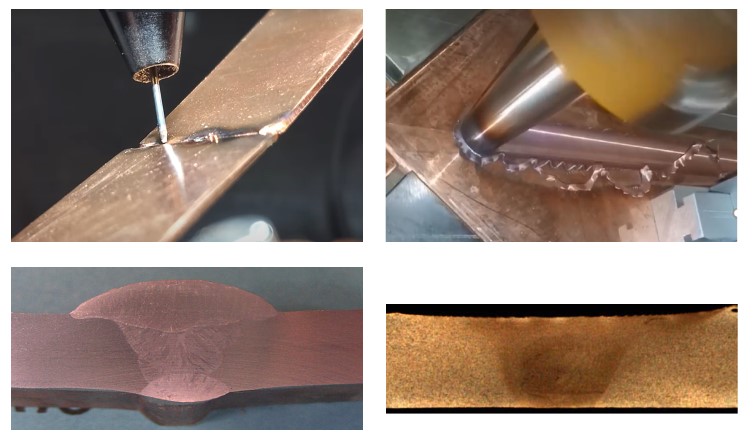

Addressing the unique joining requirements of copper bus-bar, AEE has innovatively engineered the application of friction stir welding technology. This groundbreaking approach enhances the electrical conductivity at the joint, boosts production efficiency, economizes costs, and ensures consistent high quality in the welding joints.

Comparing friction stir welding to conventional fusion welding for copper alloys, the advantages of FSW are undeniable. From welding quality, efficiency, minimal deformation, to the enhanced conductivity of the joints, FSW emerges as the superior choice in every aspect.

Comparison between FSW & ARC welding for bus-bar

Process | Arc welding | FSW |

Heat input | High | low |

Weld microstructure | cast microstructure, | fine equiaxed grains |

Deformation | high | Low |

Defect | Pore, Unfused | Tunnel defect |

Quality stability | Low; | Very high |

Consumables | Welding wire (Gas) | FSW tool (long life) |

Operator skill levels | Very high | Low |

Preparation before welding | groove,degreasing | Simple cleaning |

actions after welding | Grinding | Deburring |

Cost | High | Low |

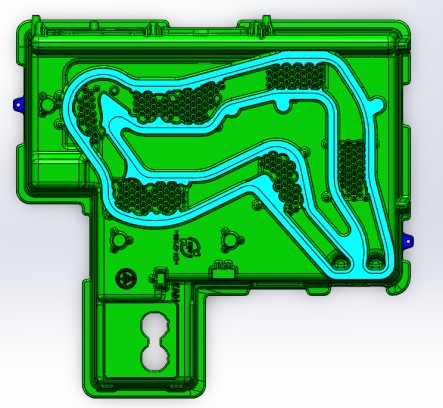

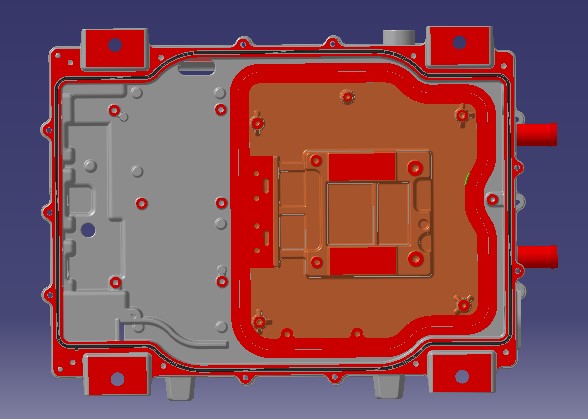

In response to this, AEE has specifically developed a friction stir welding system tailored for copper welding up to 8mm thick, along with customized welding fixtures and tools. This advanced system accommodates various combinations of copper alloys, different thicknesses, and sizes, fulfilling clients' unique production requirements. Furthermore, it also caters to the connection of aluminum alloy bus bar, demonstrating its versatility and adaptability.

The key specifications of the equipment are as follows:

Machine Type | AEE FSW 30×15/2 | |

Basic parameters | Working table(width × length) (mm) | 1500×1000 |

Machine width × depth × height(mm) | 5000×2730×4350 | |

Compressed air request | 0.6Mpa, 1m3/min, ɸ8 | |

Welding parameters | Max. welding thickness(mm) | 25 for Al and 8 for copper |

Welding Dimension(mm) | 2D | |

Traverse stroke | X-axis stroke(mm) | 1500 |

Y-axis stroke(mm) | 1000 | |

Z-axis stroke(mm) | 500 | |

C-axis stroke( 。) | ±360 | |

B-axis stroke( 。)(Manual) | 5 | |

Spindle parameters | Spindle Speed (rpm) | 2000 |

Spindle Torque (NM) | 257 | |

Spindle power(KW) | 30 | |

For Details please see FSW process for Busbar:

To delve deeper into the world of AEE and its groundbreaking achievements, kindly reach out to us via overseainfo@aeespace.com. We eagerly await the opportunity to share more about our journey and how we can collaborate to revolutionize your industry.