Aluminium Electric Control Box are Produced by FSW Process

The aluminium electric control box is one of the important components of electric vehicles, responsible for distributing the electrical energy from the battery pack to various electrical modules and cooling the electrical components.

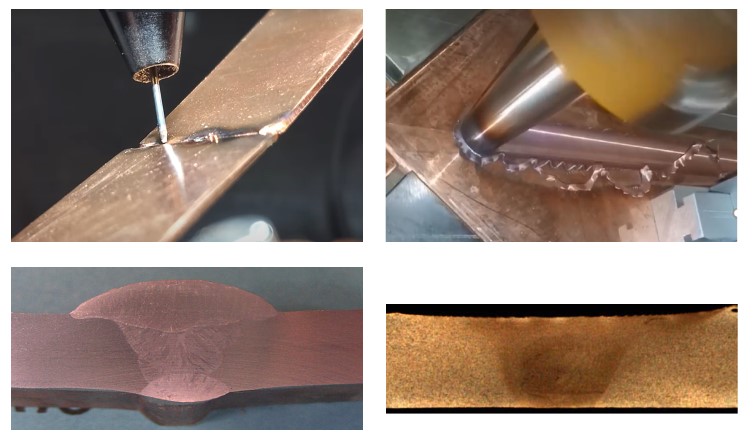

AEE has successfully achieved high-quality and efficient mass production of electric control boxes for customers by adopting friction stir welding technology. Compared to traditional welding methods such as arc welding or brazing, friction stir welding can effectively avoid defects that commonly occur during the welding of cast aluminum and aluminum alloys.

The joints obtained through this method exhibit higher mechanical properties and minimal welding deformation. Friction stir welding is highly automated, with lower welding costs, and is easy to implement for mass production.

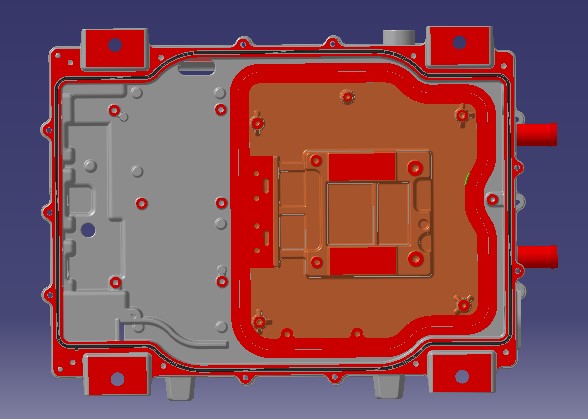

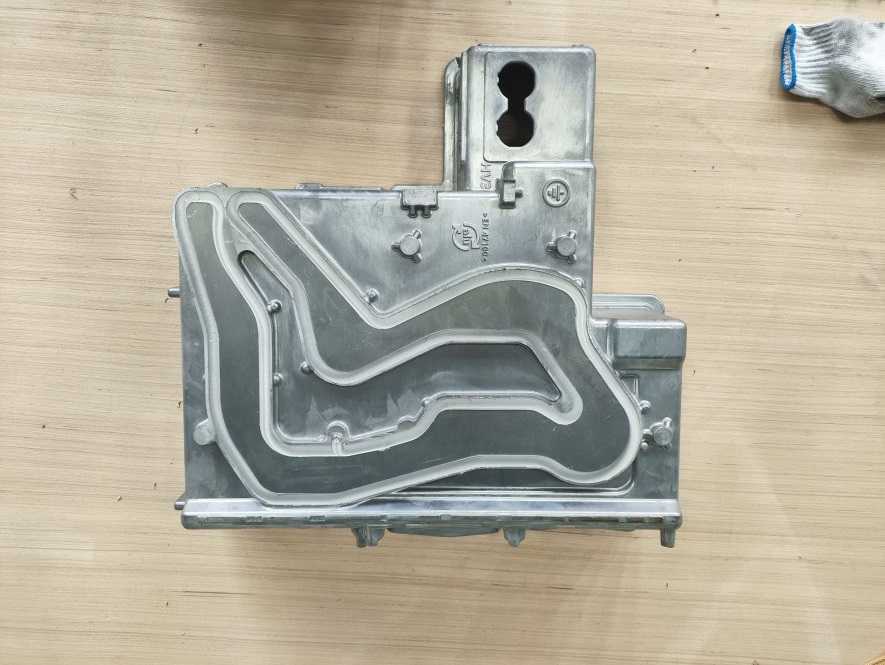

Control box shell

Cover plate

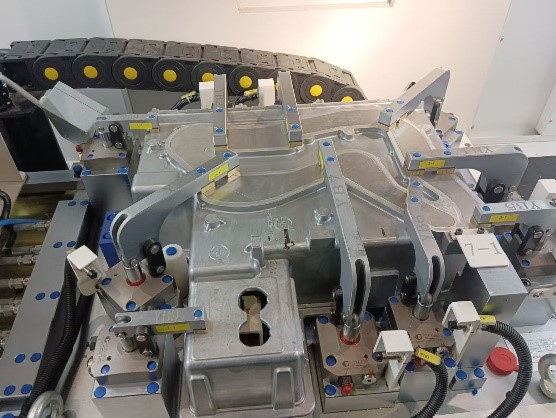

In response to the technical requirements of the customer's product, AEE provided advanced friction stir welding equipment and automated welding fixtures. Leveraging its extensive experience in FSW process, AEE successfully produced electric control boxes with aesthetically pleasing weld surface finishes, excellent mechanical properties of the welds, minimal welding deformation, satisfactory leakage performance, and stable welding quality.

After welding

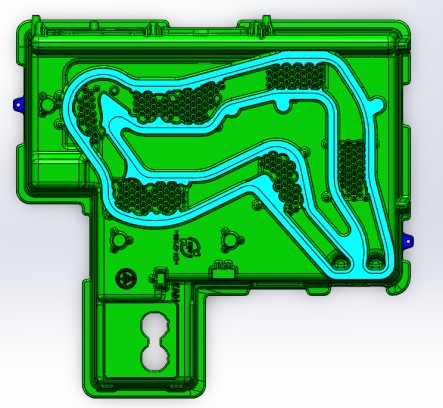

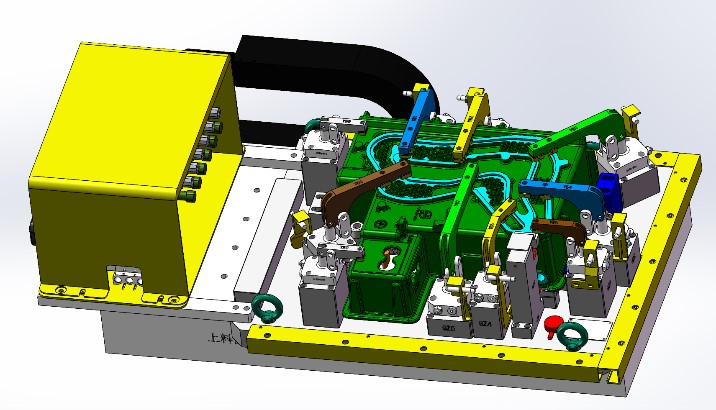

C-type FSW Machine for electric control box welding

The key specifications of the equipment are as follows:

Machine Type | AEE FSW 8X10/2 | |

Basic parameters | Working table(width × length) (mm) | 1200×600 |

Machine width × depth × height(mm) | 2900×2900×2500 | |

Compressed air request | 0.6Mpa, 1m3/min, ɸ8 | |

Welding parameters | welding thickness(mm) | 2mm-8mm |

Welding Dimension(mm) | 2D | |

Traverse stroke | X-axis stroke(mm) | 1000 |

Y-axis stroke(mm) | 600 | |

Z-axis stroke(mm) | 300 | |

C-axis stroke( 。) | ±360 | |

B-axis stroke( 。) | 5(Manual) | |

Spindle parameters | Spindle Speed (rpm) | 4000 |

Spindle Torque (NM) | 112 | |

Spindle power(KW) | 12 | |

Automatic FSW fixture

· Hydraulic fixture with strong force

· Central control by FSW Siemens system

· Follow-up pressing

· Pre-deformation strategy.

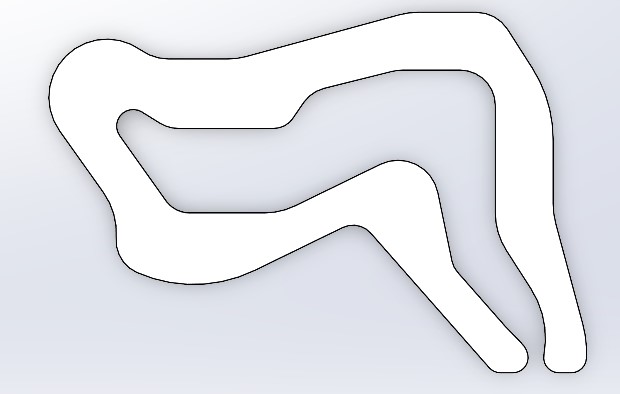

The FSW tool

AEE customized Friction stir welding tools for die-casting aluminium alloy, made of special tool steel, with long lifetime and excellent performance.

To delve deeper into the world of AEE and its groundbreaking achievements, kindly reach out to us via overseainfo@aeespace.com. We eagerly await the opportunity to share more about our journey and how we can collaborate to revolutionize your industry.