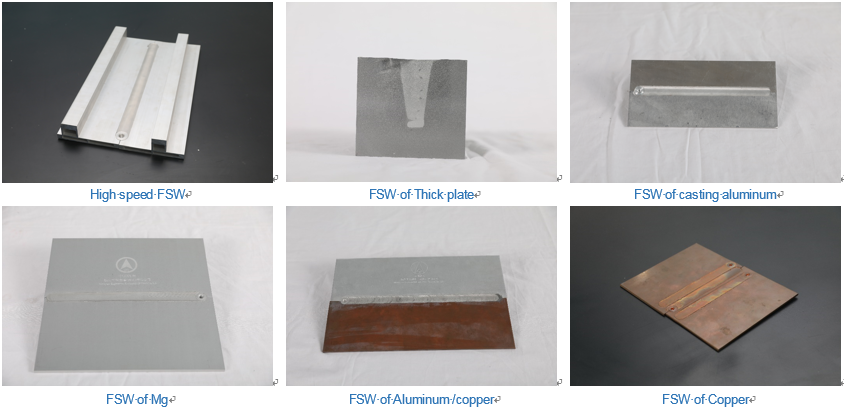

Friction Stir Welding (FSW) is a solid-state joining process invented in 1991 by The Welding Institute (TWI) in the UK. This solid state process leads to minimal microstructural changes and better mechanical properties than conventional welding. Friction stir welding (FSW) has been successfully used on high-strength aluminum alloys that are typically difficult to weld.

■ Low distortion and residual stresses

■ Improved microstructure and fatigue strength

■ Fully automatable and monitoring

■ High degree of reproducibility

■ No filler material or welding consumable required

■ Environmentally friendly fabrication process