Carry on the past and open the future, AEE continue to help the aluminum industry to innovate and upgrade

Carry on the past and open the future,AEE continue to help the aluminum industry to innovate and upgrade

ALUMINIUM CHINA was held in Shanghai New International Expo Center from July 7 to 9, 2021. Aerospace engineering equipment (Suzhou) Co., Ltd. participated in the event as an expert in friction stir welding.

Familiar friend

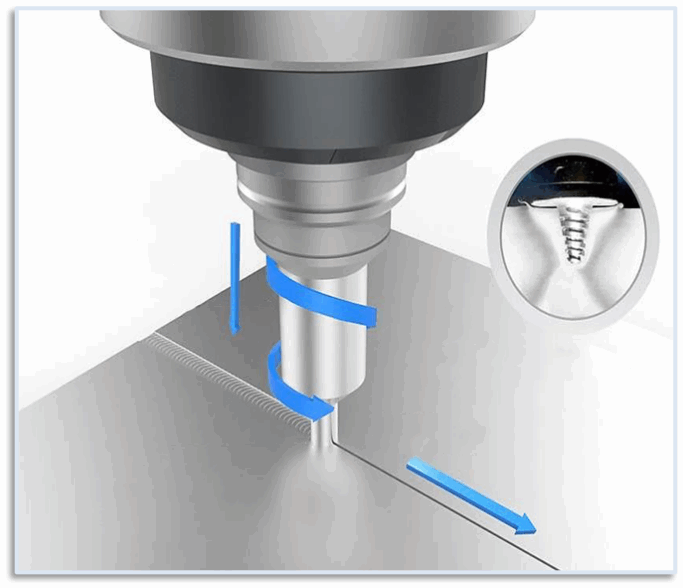

As a new revolutionary connection technology, friction stir welding has been showing its advantages in the application of aluminum industry since its inception, which also makes us quickly change from a new friend of "aluminum Exhibition" to a "familiar friend ". During the exhibition, AEE was pleased to meet too many old friends and promote the rapid development of aluminum alloy industry with our new technology.

From conquering the friction stir welding technology of space rocket storage tank to realizing the large-scale mass production of ship profiles, AEE has achieved from single piece and small batch to the delivery of large quantities of process equipment.

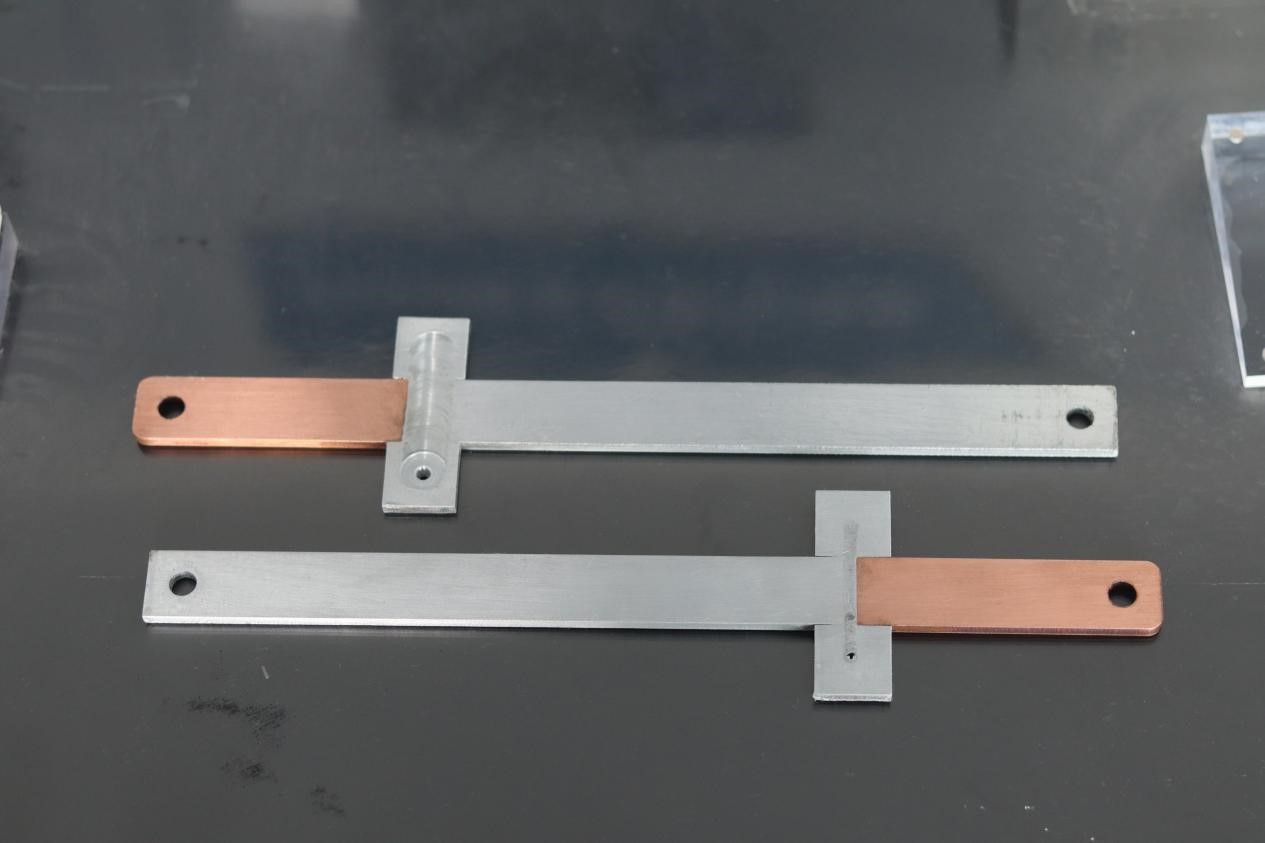

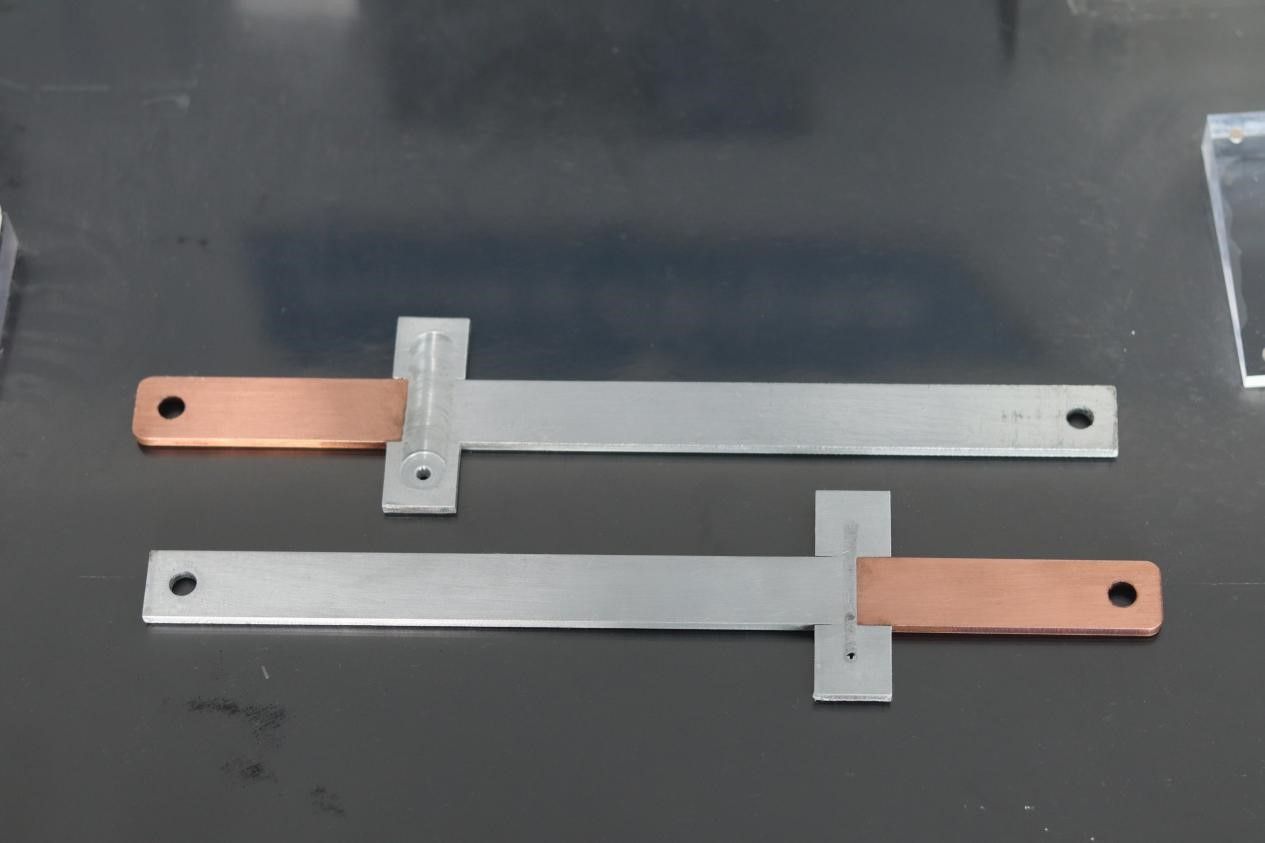

In order to realize the welding of finned radiator with larger cross-sectional area, AEE brought the military-grade FSW technology to the civil industry through standardized design, and realized the popularization and application of FSW technology in the radiator industry.

From breaking the technical barriers and realizing the application of "double shoulder" welding technology, to the development of a dual-station intelligent equipment with "one-key start" for the 22-meter car body floor, we have spent 10 years and successfully helped the rail transit industry to solve the problem of automatic welding of aluminum profiles.

Automobile aluminum wheels, new energy DCDC, water-cooled electric control box, water-cooled motor housing, three-in-one motor, heat pump, high-pressure valve body, intelligent friction stir welding equipment for automobile battery box equipped with laser welding seam tracking and visual operation interface…

AEE keeps up with the development of the automobile industry, helps users realize more lightweight automobile parts, and expands the application boundary of aluminum alloy.

New opportunities

With the upgrading of industrial technology and the establishment of more and more foreign-funded R&D centers in China, the positioning of AEE has gradually shifted from being a "world factory" to becoming a global innovation center. The independent controllability of process and equipment technology is the foundation of technological innovation. After 20 years of research and development, we have realized FSW of dissimilar metals, high melting point materials, ultra-thick plates and space curved surfaces, and conquered cutting-edge technologies such as keyhole-free and micro-stirring in the application of aerospace products, so as to make process reserves for the development of more new products.

The pedigree mixing tool and friction stir welding database management system including single shaft shoulder, double shaft shoulder, static shaft shoulder and friction stir welding can directly reduce the technical threshold of new users and help production companies realize technical application as soon as possible.

Serial FSW equipment realizes large-scale mass production of products through welding force control system, mixing tool life control system, welding teaching function, user hierarchical control function and automatic follow-up tooling.