Heavy-duty Dynamic Gantry Friction Stir Welding Equipment was successfully delivered to the customer

The heavy-duty dynamic gantry friction stir welding equipment, which was independently developed and designed by Aerospace Engineering Equipment (Suzhou) Co., Ltd. (hereinafter referred to as “AEE”), was recently packaged and delivered to customers in the rail transit field: Quality supplier of Zhuzhou Lince Group Co., Ltd. — CRRC Zhuzhou Locomotive Co., Ltd.

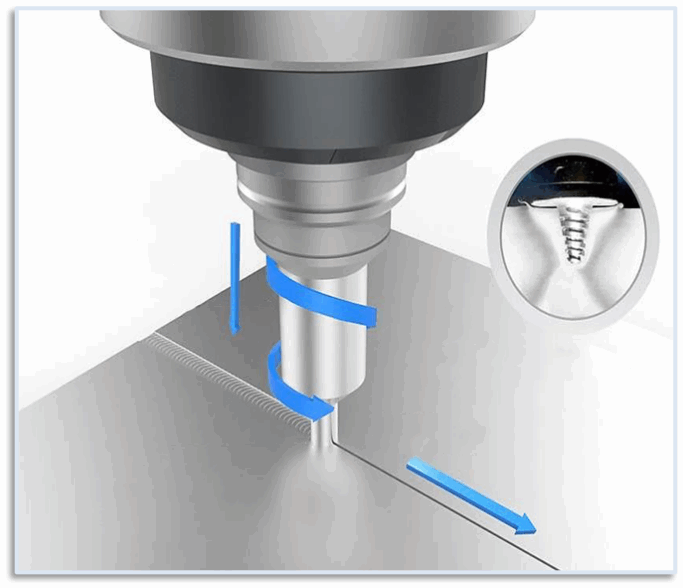

This equipment is mainly used for the welding of traction beam and sleeper beam in rail transit field. It is helpful to solve the problems of large welding distortion, low performance, multi-lager and multi-pass welding in traditional aluminum alloy fusion welding of medium and thick plates, and effectively improve the welding quality and welding efficiency.

The equipment is suitable for the welding of 1XXX~8XXX series of aluminum alloy materials, and can complete single-sided friction stir welding of aluminum alloy plates or profiles with a thickness of 2-30mm, a width of ≤3000mm, and a length of ≤4000mm. In addition, the equipment is equipped with a special heavy-duty A-axis swing system for medium and thick plates, which can realize any angle adjustment within the range of ±30° on the A-axis, can realize the welding of flat straight welds and spatial bevel welds. The equipment can be applied to mass production.

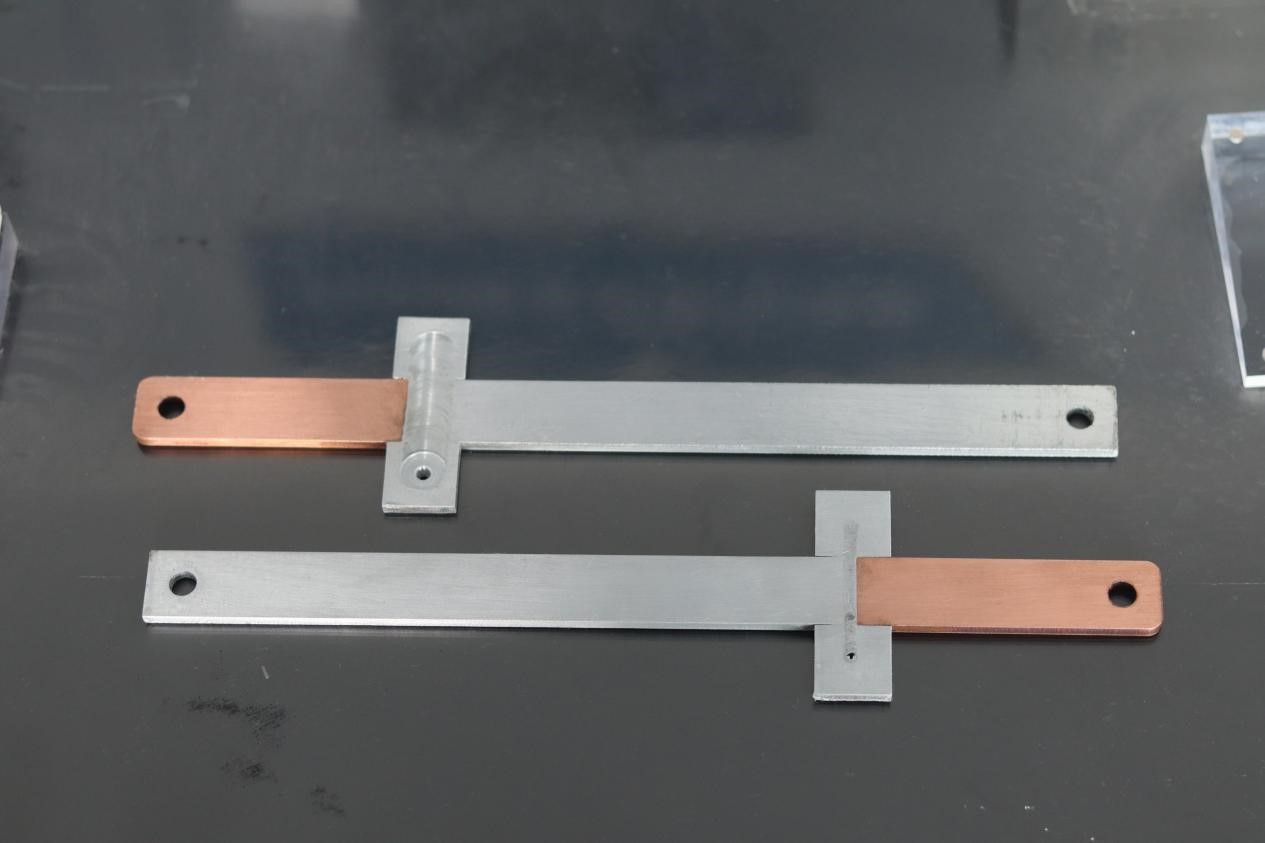

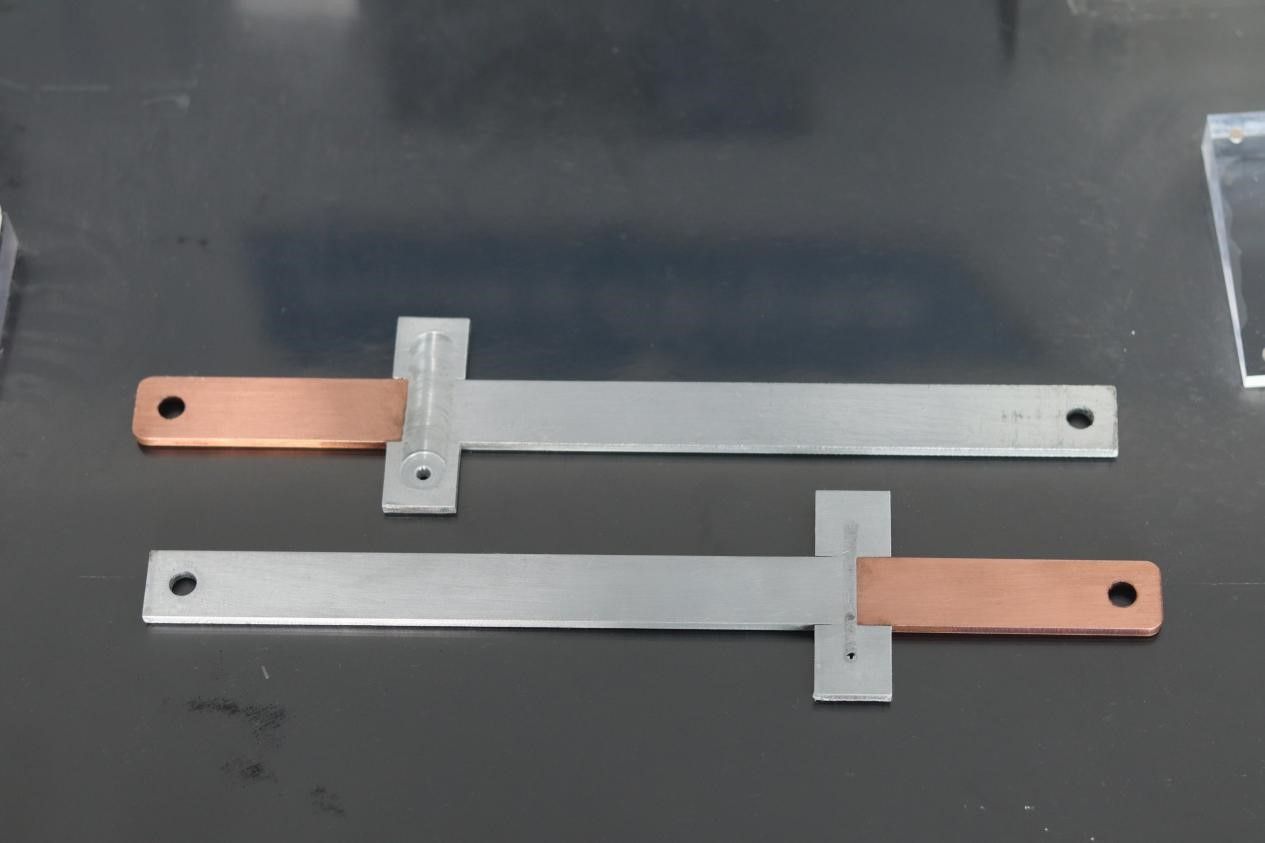

Adaptive tooling

Products after welding

Main configurations and functions of the equipment:

1. The Use of high-precision servo control and gantry moving constant tension electric anti-backlash technology has enhanced the stability of the high-precision synchronous movement of the gantry.

2. Equipped with a fast response constant pressure control system, which realizes the automatic high-speed welding of the product.

3. Equipped with real-time high-definition video surveillance system.

4. Equipped with a welding seam laser tracking system, which can realize automatic correction of the welding seam.

5. Equipped with welding pressing system to assist product pressing, improve product configuration and overall gap, and help improve welding quality.

6. With reference to the aerospace safety requirements, create a comprehensive safety protection system.

7. Equipped with a constant temperature independent operating room, it provides customers with a comfortable and user-friendly operating environment.

Inside of operating room

Parts of equipment head

With the unity and cooperation of project team members, the progress has been highly recognized by customers. The pre-acceptance of equipment has been completed in early August 2021.

Group photo of project team members and equipment

The smooth R&D and delivery of heavy-duty dynamic gantry friction stir welding equipment has further expanded the reputation and influence of AEE in the friction stir welding market in the rail transit industry. And it is a strong confirmation of the aerospace quality in China’s manufacturing.

With the implementation of development plans such as “Made in China 2025”, AEE will further improve the level and production efficiency of intelligent equipment, continue to strengthen technological innovation, attach importance to technical reserves, quickly and efficiently provide the best solution for welding manufacturing and provide customers with system integration and technical services for medium and high-end equipment.