FSW, friction stir welding, welding equipment, serbia, battery trays, accessories, Minth Group

March 10th, in Loznica, Minth Group held a grand opening ceremony to celebrate the completion of the construction and initial of production of the factory of Minth Automotive Loznica, concurrently with the groundbreaking for new factories in Serbia. The President of the Republic of Serbia, Aleksandar Vučić attended grand opening ceremony and delivered an important speech. Prior to this, the gantry FSW equipment provided by Aerospace Engineering Equipment (Suzhou) Co., Ltd. for the production of lightweight aluminum alloy battery trays for this factory had successfully passed the acceptance and delivery at the customer site after installation, commissioning and stable operation.

▲Serbian President Delivered An Important Speech

(Images from "Minth Group" Official Account)

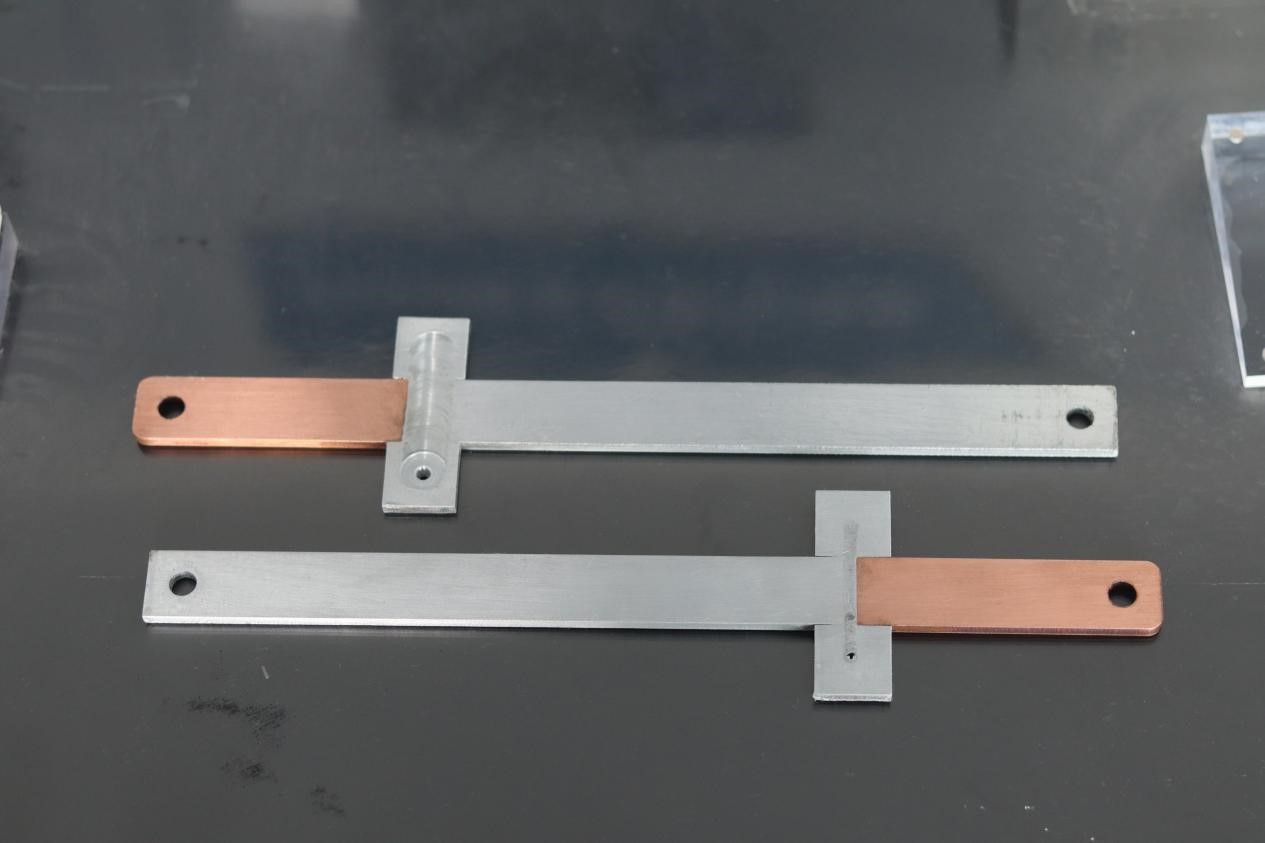

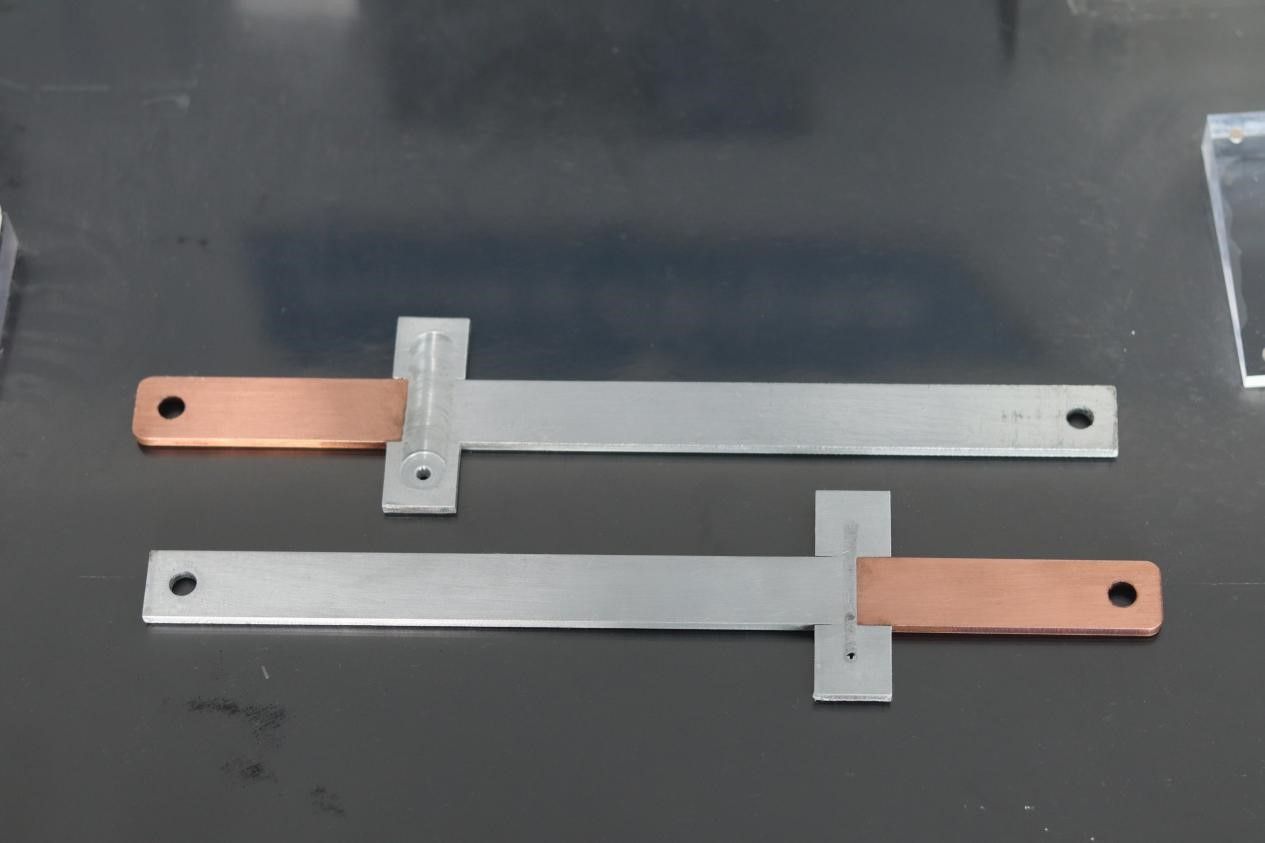

After the opening ceremony activities, President and his VIP guests visited the BCB production line of the B2 factory in Loznica, including welding, CNC, cleaning, assembly, measurement and other processes, and the assembly of highly automated welding line phase I and phase II. It is reported that the main products are aluminum alloy battery boxes and accessories.

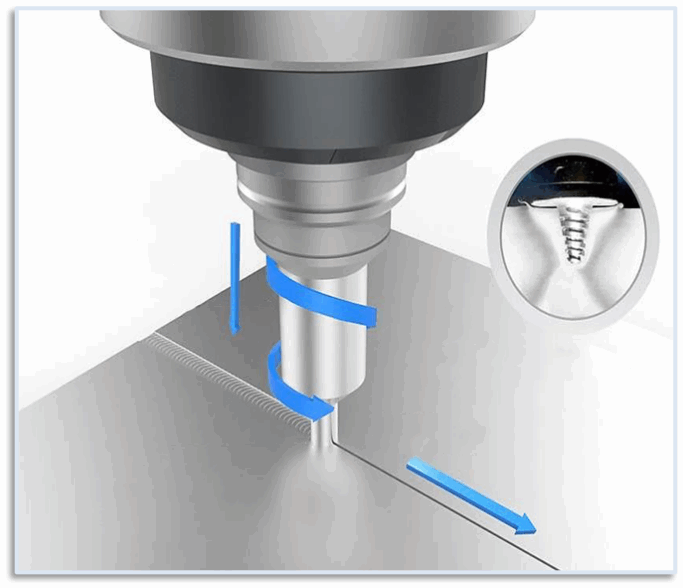

1. Intelligent welding helps automate production

The upgraded gantry type FSW equipment provided by AEE for the welding line has high reliability, high efficiency and intelligence performance. The equipment can realize 4000rpm high speed welding, and also integrate the newly developed and upgraded welding force control system to weld aluminum alloy battery trays and accessories with high quality, which helps the welding line of this factory to realize fully automated production of FSW stations and solve the problem of special process and complex control on site. No manual intervention is required throughout the welding process, thus realizing fully automated production of products.

▲Gantry FSW equipment for the production of lightweight aluminum alloy battery trays

2. Fulfill of mission, rushed to the scene

During the whole installation, commissioning and operation process, facing many tests such as the intensification of the epidemic in Europe and the meltdown of international flights, AEE paid close attention to the changes of the epidemic situation overseas and made active preparations for smoothly going to the customer's first-line service site. At the customer's site, the company's technical engineers actively cooperated with the customer to promote the installation and commissioning of the equipment, and won the customer's full affirmation and high praise by virtue of excellent equipment performance, welding quality and good service, and expressed their expectation of follow-up and further close cooperation.

▲Staffs of AEE in Serbia equipment delivery site

The successful delivery of the company's FSW equipment for the production of lightweight aluminum alloy battery trays provides customers with advanced welding solutions for electric vehicle aluminum alloy battery trays and accessories, which will be applied in Serbia and the Czech Republic for Mercedes-Benz, Volkswagen, Renault and other automotive brands, providing fast localization services for the whole European market.

In the process of Chinese enterprises' contribution to driving local employment in Serbia and even promoting the overall economic development of the "Belt and Road" countries, the company has also made its contribution with excellent product quality and strong technical strength, which also shows the responsibility and commitment of the company as a member of China Aerospace.