Process development of Stationary shoulder friction stir welding

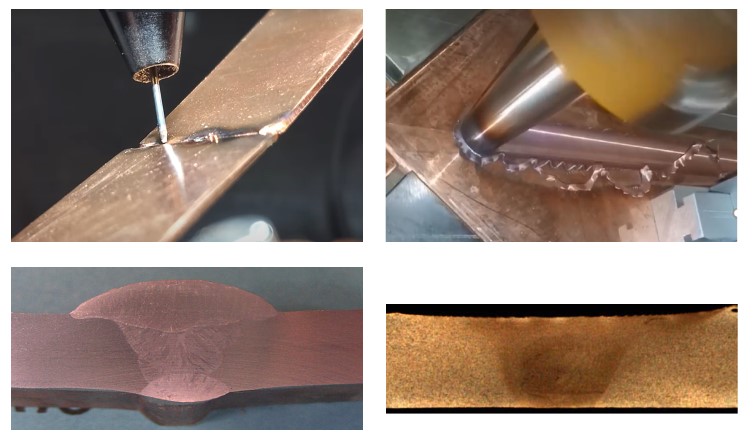

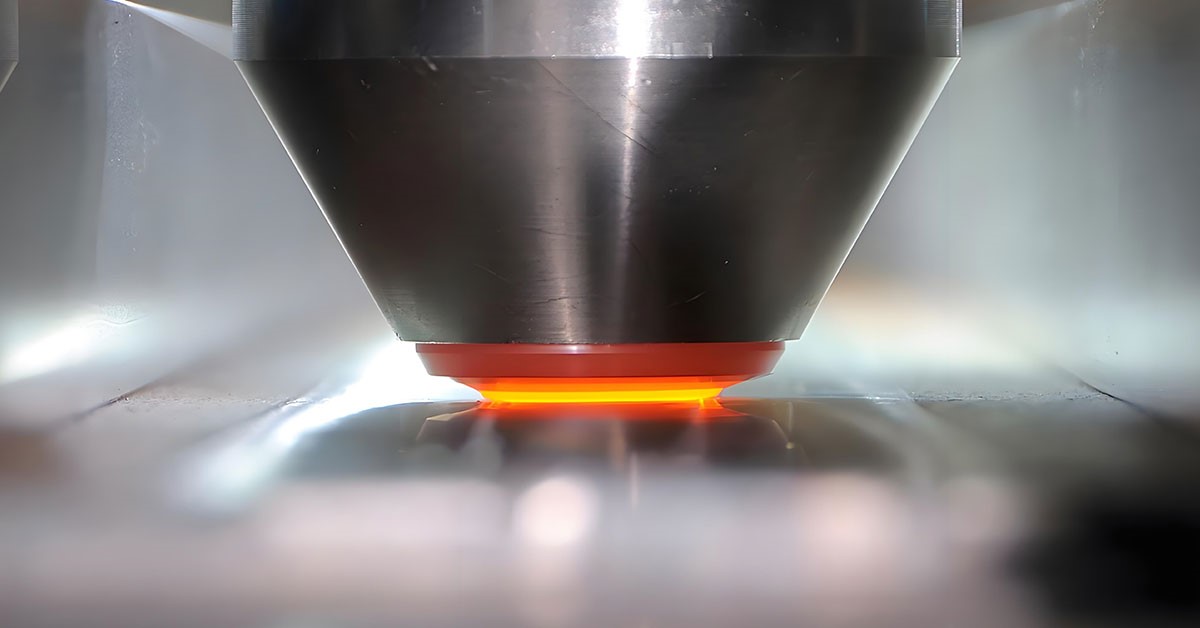

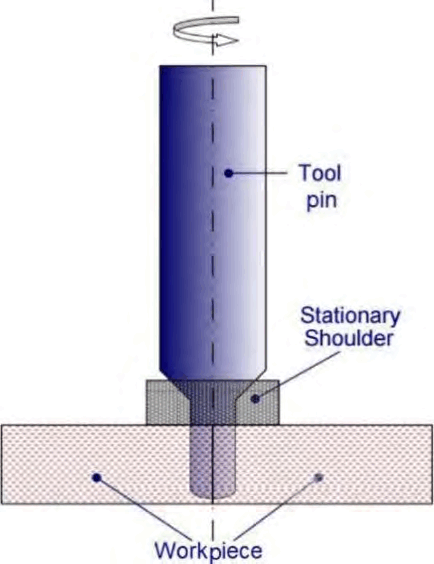

During SSFSW, heat generation and material flow are mainly provided by the rotating pin, which are completely different from those in conventional FSW.

The heat generation provided by the rotating pin during conventional FSW is only 20~30% of the total heat input.

The optimal welding parameters that are beneficial for obtaining good joints in traditional FSW processes may not be applicable to SSFSW, due to insufficient frictional heat and material flow caused by the frictional heat loss generated by the rotating shoulder.

There are obvious differences in welding parameters between conventional FSW and SSFSW.

process development ssfsw

In addition, SSFSW can prevent plasticized materials from overflowing from the weld seam under extremely high heat input and broaden the welding parameter window.

According to the theories of heat generation during FSW, heat input is closely correlated with base properties of work-pieces (yield strength, hardness, etc.), welding parameters (welding speed,rotational velocity, plunge depth, etc.) and equipment parameters (shoulder or pin diameter, pin morphology, etc.).

Additionally, aiming at the SSFSW of dissimilar materials, the welding parameters depend on the materials or joining types (butt or lap joints).

For dissimilar materials with severe inter-facial reactions, mechanical interlocking and metallurgical bonding are attributed to the joint strength.

Scholars have suggested that a rotation speed of 1000 rpm may be the reason for sufficient heat input, while a low welding speed of 60mm/min can provide more stirring time to improve the mechanical interlocking of aluminum and magnesium alloy.

High welding speeds above 60mm/min can easily lead to welding defects. With the assistance of ultrasonic treatment, welding defects can be further increased to 80mm/min.

When using polymer in the upper part and metal in the lower part of the lap configuration, the selection of welding parameters should comply with the connection of the polymer, which requires a relatively low welding speed of less than 50mm/min, without the need for a secondary heating system.

For lap joints of similar or different materials, the process changes are different from those of butt joints.

The rotation speed of butt joints is relatively low, and the welding speed is slightly higher because the original interface in the butt joint disappears in the upper piece of the lap weld.

About application of Stationary shoulder friction stir welding, more information can be found on the website: https://a-fsw.com/

#Friction Stir Welding #Stationary shoulder friction stir welding #SSFSW #Aluminum alloy