Application of Friction Stir Welding in Semiconductor-Liquid Cooling Plate

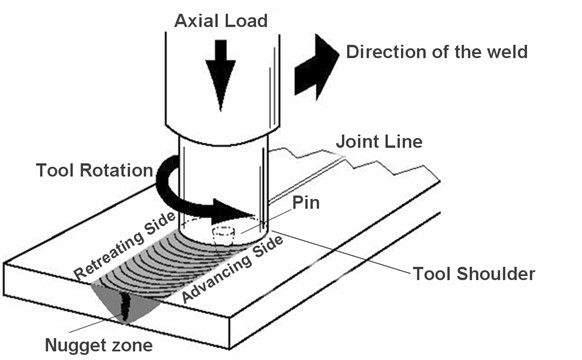

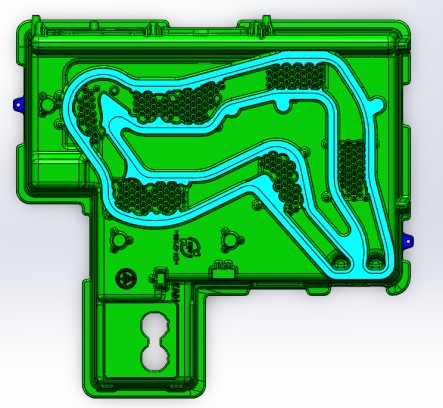

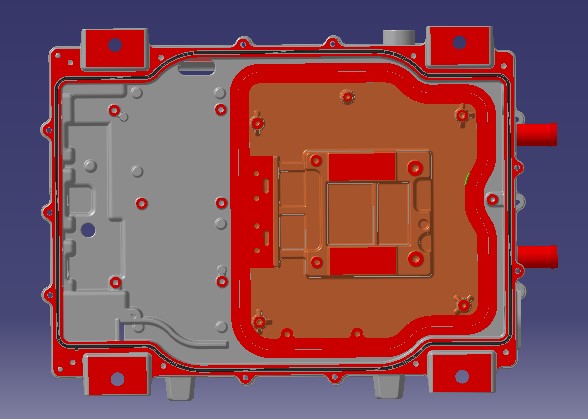

Liquid cooling plates are widely used in the cooling of components and the liquid crystal panels, semiconductor instruments, and the susceptor of the chemical vapor deposition equipment. The material of the liquid cooling plates must have good thermal and electrical conductivity, and require very low smoke emission, Copper alloys are usually used. To manufacture a liquid cooling plate with high cooling efficiency will involve grooving the panel, sealing the groove with a cover plate, and performing multiple processes of surface machining to ensure that a liquid-cooling channel is formed in the liquid cooling plate. The traditional electron beam welding technology is used to weld the liquid cooling plate and the cover plate of the sink, which will cause deformation due to heat and poor performance in the area near the weld. The friction stir welding technology is used to manufacture, because the welding temperature is reduced, it can ensure the smallest deformation, and can produce large-scale high-efficiency liquid cooling plates in batches. The performance of the welded joints between the liquid-cooled plates and the sink cover is good, suitable for copper alloy liquid Mass production of cold plates.

The demand for LCD panel TVs has been increasing, the popularization of digital media, the emergence of new digital video standards, and the growth in demand for such products have all suppressed a significant increase in the demand for liquid cooling panel products. AEE Lightweight has carried out process testing and development of copper alloys, continuously optimizing the design of mixing head, process parameter setting and welding auxiliary device design, and has many successful cases.