Dynamic beam and gantry five-axis FSW equipment successfully completed on-site installation and commissioning during the Chinese New Year

On January 9, 2022, with the first car of parts into the installation site of Shanghai Aerospace Equipments Manufacturer Co., Ltd., it announced that the site installation and commissioning of the dynamic beam and gantry five-axis FSW equipment officially started. During the Spring Festival in 2022, the installation and commissioning of the five-axis dynamic gantry FSW equipment was successfully completed by the project team and the cooperation of all departments of the company.

Part.01 Work together and strictly adhere to the timeline

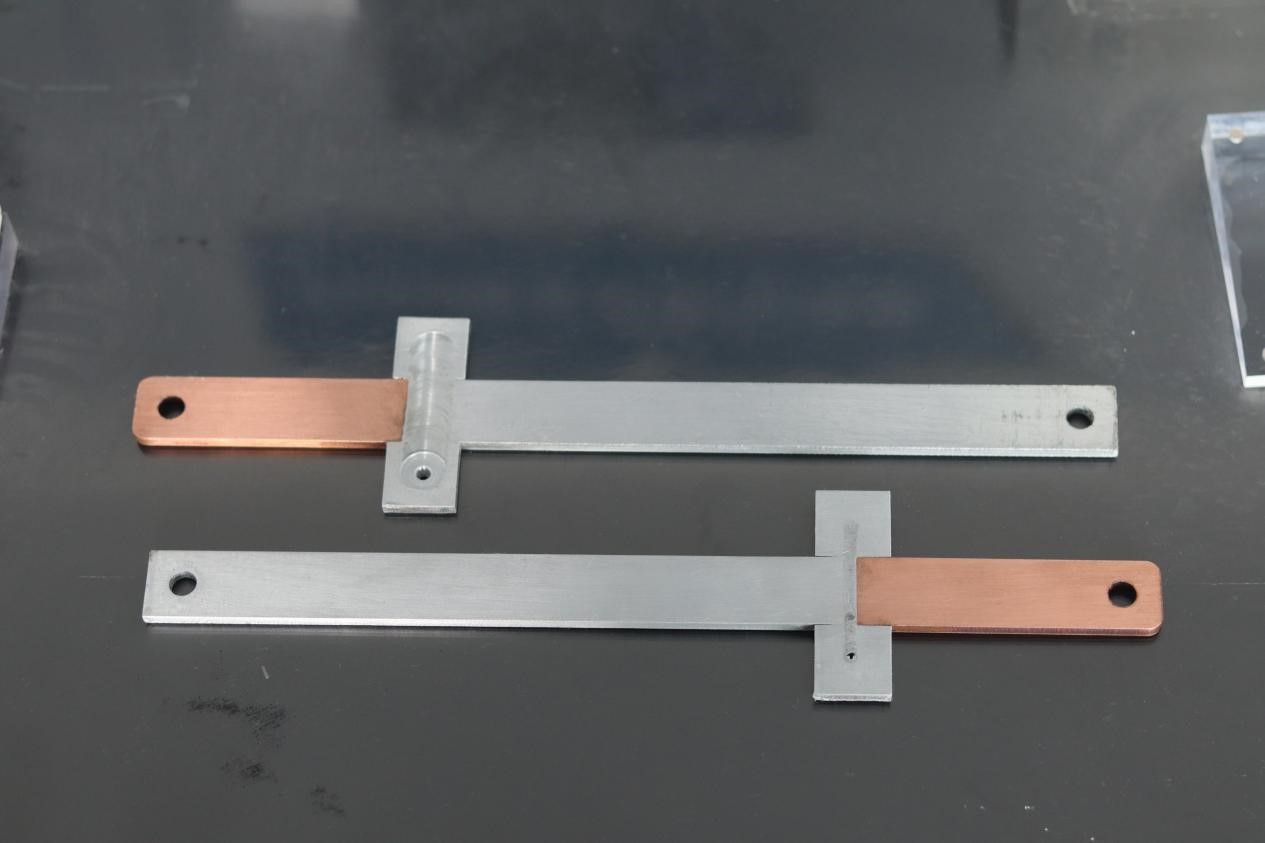

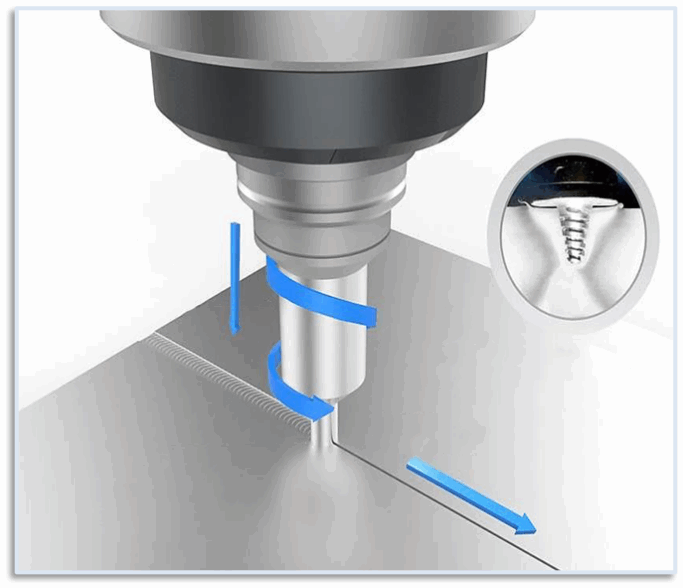

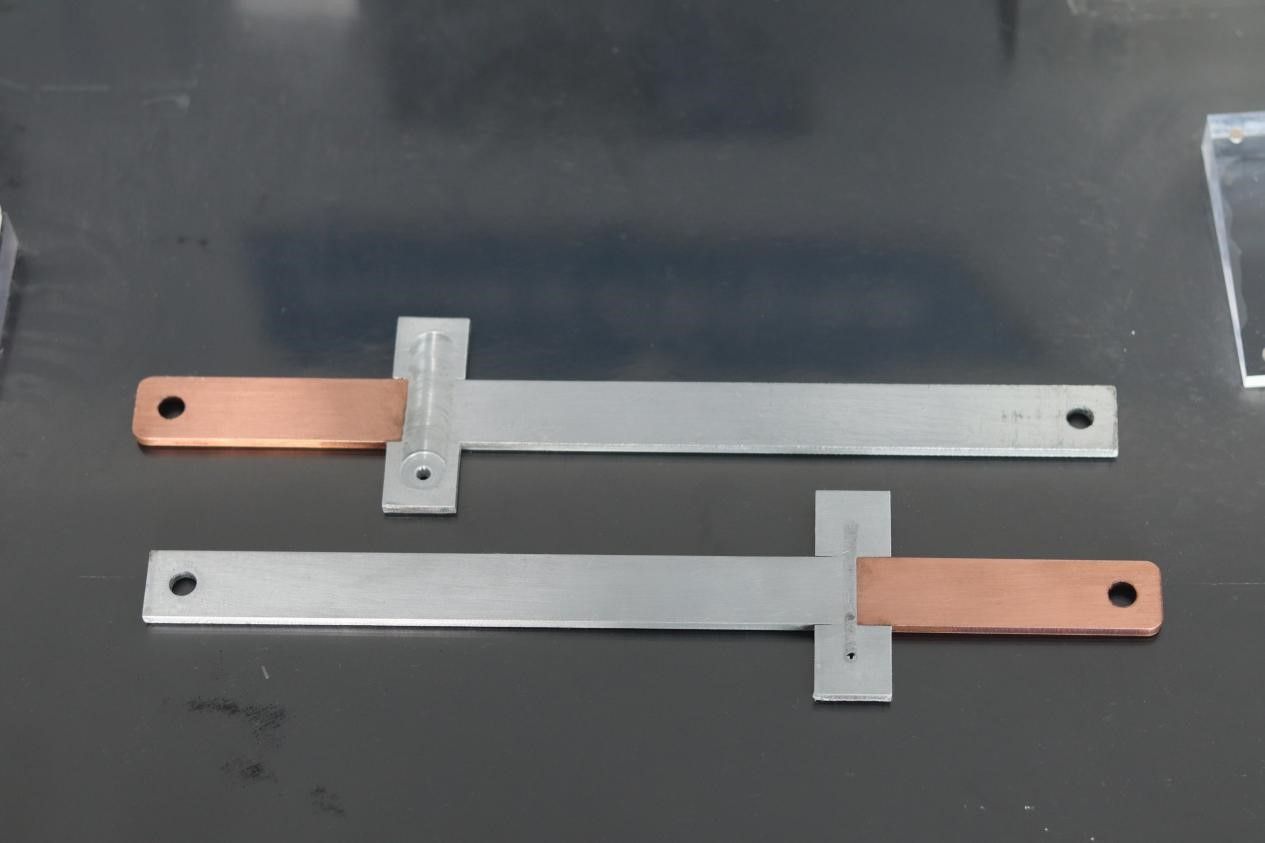

The dynamic beam and gantry five-axis FSW equipment is used for welding the longitudinal/annular seam of the rocket fuel storage tank. The project started in August 2021 and the power-up commissioning was completed on February 1, 2022. It was difficult to complete such a huge object in 7 months.

Under the care and support of leaders, the project team staff persevered with the project goal and firm beliefs. The project was set up in August and the scheme design was completed in early September, which shortened the time by half compared with general non-standard projects. During the period, the team continuously communicated with suppliers, drew up the plant production plan and catch-up plan, and ensured that the preassembly and commissioning of the company's first dynamic beam and dynamic gantry friction welding equipment was completed by the end of December 2021. On January 2, the power supply was officially turned on for commissioning, and the first component was delivered on January 9. In order to ensure the completion of the installation and commissioning before February 1, the company's leadership and project team members are working together, opening a "fierce battle to the end" mode of work, and striving for the precise implementation of the project nodes.

Part.02 Tackling difficulties and improving to ensure quality

As the project was the first case of dynamic beam and dynamic gantry equipment in the company, the project team lacked design reference data and experience in relevant cases, thus making the equipment design process difficult. At the same time, after the arrival of the dynamic beam and dynamic gantry five-axis friction stir welding equipment components in early November, the time left for the installation and commissioning team was less than 2 months. Although the work content was to revive the already built structure, this time the requirements were more demanding and the details were more complicated, which was a severe test for the project team.

However, the project team showed an attitude of excellence in the face of difficulties. According to the project designer's recollection, the project carried out as many as a dozen reviews, the equipment program was pushed back and rebuilt three times, and the selection of outsourcing parts was returned five times. Through setbacks and a month of struggle, the drawings were finally completed and put into production in early September. Starting from January 10, the installation and commissioning of the dynamic beam and gantry five-axis friction stir welding equipment was carried out by the installation and transfer team in the form of shift change. In order to ensure the progress and quality, the whole team arranged 12 people for the installation and commissioning to ensure that the equipment could be completed and energized before the Spring Festival. During the Spring Festival holiday, the project team even went to work overtime after a short break, so that the project formed capacity in a short time and ensured the timely execution of production tasks.

Part.03 Meet customer needs, actively fight to ensure delivery

During the project, the project team members paid close attention to the progress and quality of every step of the project, and actively fought for 7 months with the goal of successfully delivering to the customer and satisfying them.

The design team repeatedly deliberated on the plan, the production department kept a close eye on the production schedule, and formulated an action plan immediately when production delays were found. Finally, with the collaboration and cooperation of various departments, all the big parts reached the workshop site of the equipment company in early November. The person in charge of equipment site installation said: "If the installation in the company does not pass, it will seriously delay the time of site installation and commissioning. Therefore, every step must be done properly during the first installation to ensure the smooth implementation of on-site installation and commissioning and to meet the customer's requirements."

From project inception to program design, from supplier exchange to the completion of installation and commissioning, a full seven months, the entire team persevered, used to struggle, and turned the fight and struggle into the main theme of the Spring Festival, and finally successfully completed the goal before February 1.

In the new year, the whole company will be united to carry forward the aerospace spirit of the new era and start a new journey of the Chinese dream and aerospace dream!