Classification and characteristics of Friction Stir Welding tool

Classification and characteristics of Friction Stir Welding tool is one of the core part for friction stir welding process, which is honored to be the "heart" of FSW process.

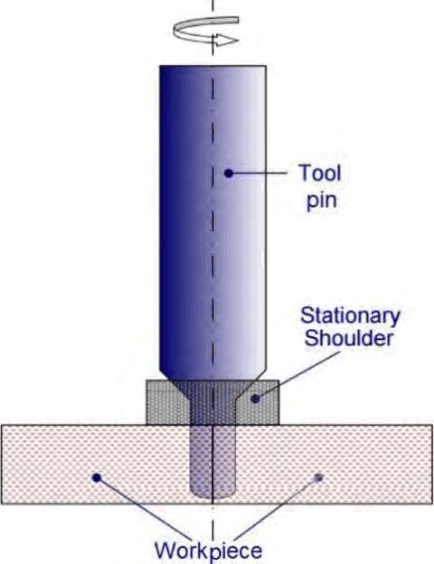

FSW tool is also the special consumable of FSW process and mainly composed by pin and shoulder.

Friction Stir Welding tool

During the FSW process, the FSW tool rotates at high speed and slowly squeezes into the unwelded work-piece until the shoulder closely contact with the work-piece surface.

FSW tools can be distinguished according to different classifications.

According to the type of welded joint, FSW tools can be divided into series series:

conventional FSW tool;

retractable FSW tool;

bobbin FSW tool;

stationary-shoulder FSW tool;

Friction stir spot welding tool.

Here are some common types of FSW tools and their characteristics:

Conventional FSW tool: This is the most traditional friction stir welding tool and is suitable for the joining of aluminum and magnesium alloys.

It has one shoulder and one pin, which generates frictional heat by rotating at high speed to heat the metal material to be welded to a plastic state, and then extrudes and forges to realize the connection of the material.

Retractable FSW tool: This type of FSW tool is suitable for circle weld seam and achieve the no key-hole process.

The retractable FSW tool has a retractable pin, which extends for a certain length before the welding starts, and then retracts to get no key-hole weld seam after the welding is completed.

Bobbin FSW tool: This type has two shoulders and is suitable for hallow extrusion profiles, the joint are with better lightweight effect than the conventional joint.

Due to the heat production from the upper and lower shoulders of the bobbin- friction stir welding, the micro-structure of the upper and lower layer of the welded joint is more uniform than the conventional joint.

Stationary shoulder FSW tool: This type of FSW tool keeps the shoulder stationary while the pin rotates and feeds during the welding process.

SSFSW is available for the weld of different thickness, complex curve & any angle.It is suitable for welding some special shaped parts or occasions where the deformation of the work-piece needs to be avoided.

Refilled FSSW tool:This kind of joint is suitable for overlap spot joint between aluminium, magnesium, copper and even steel.

Through the relative motion of the pin and the sleeve, a solid-phase spot welding joint is achieved, the welding quality is much better than the resistant welding process.

AEE have developed standard FSW tool to meet different thicknesses and structural forms according to different application and requirement.

Besides we also invest lots of resources to design and test customized FSW tools according to the specific welding requirements.

About Friction Stir Welding, more information can be found on the website: https://a-fsw.com/