Ultrasonic metal welding

Ultrasonic metal welding is a special method that uses mechanical vibration energy of ultrasonic frequency to connect the same or dissimilar metals. When metal is ultrasonically welded, neither electric current nor high-temperature heat source is applied to the workpiece, but under static pressure, the vibration energy of the frame is converted into friction work, deformation energy and limited temperature rise in the work room. The metallurgical bonding between the joints is a solid state welding that is achieved without the base material being melted.

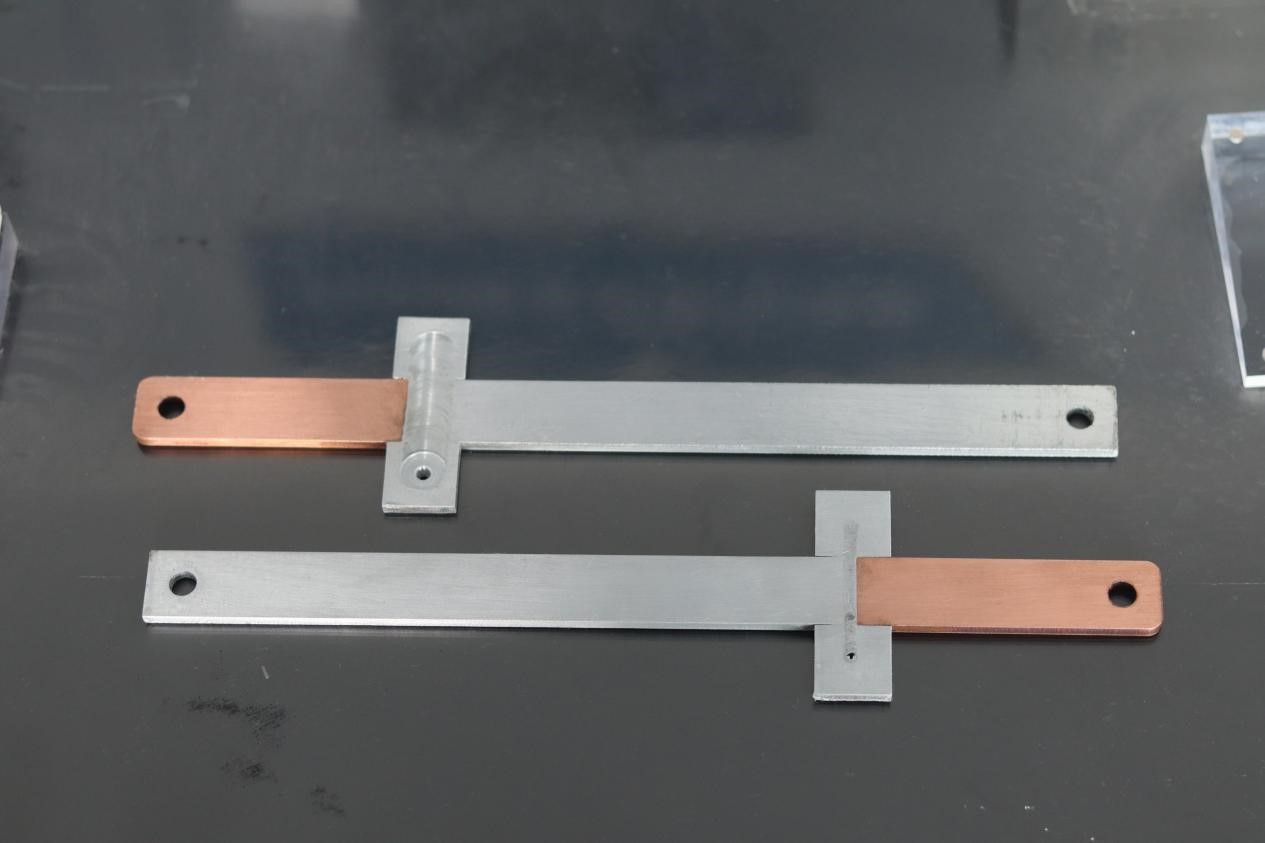

It effectively overcomes the phenomenon of spatter and oxidation during resistance welding. Ultrasonic metal welding machine can perform single-point welding, multi-point welding and short strip welding on the thin wire or sheet materials of non-ferrous metals such as copper, silver, aluminum, nickel, etc. Shaped welding. It can be widely used in the welding of SCR leads, fuse pieces, electrical leads, lithium battery pole pieces, and tabs.

The advantages of ultrasonic metal welding are that it is fast, energy-saving, high fusion strength, good conductivity, no sparks, and close to cold processing; the disadvantage is that the welded metal parts cannot be too thick (generally less than or equal to 5mm), and the welding point cannot be too large.