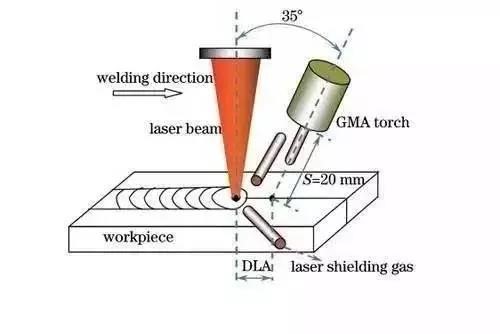

Laser Hybrid welding

Laser hybrid welding is the combination of laser beam welding and MIG welding technology to obtain the best welding effect, fast and weld bridging ability, and is the most advanced welding method currently.

The advantages of laser hybrid welding are: fast speed, small thermal deformation, small heat-affected area, and ensure the metal structure and mechanical properties of the weld.

In addition to the welding of automotive thin-plate structural parts, laser hybrid welding is also suitable for many other applications. For example, applying this technology to the production of concrete pumps and mobile crane booms. These processes require the processing of high-strength steel. Traditional technologies often require other auxiliary processes (such as preheating) to increase costs. Furthermore, the technology can also be applied to the manufacturing of rail vehicles and conventional steel structures (such as bridges, fuel tanks, etc.).