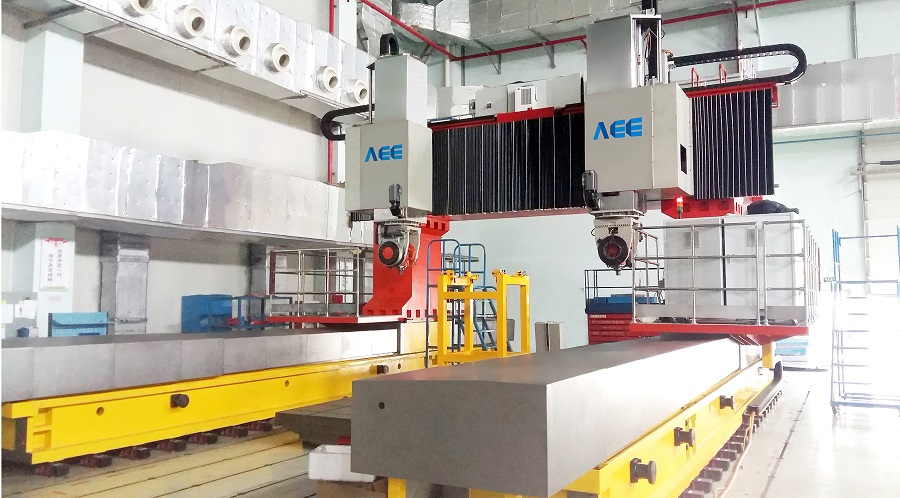

Dynamic Gantry FSW machine

Dynamic gantry friction stir welding machine is developed for large-scale flat products' butt-joining, and it is assembled with different welding spindle and drive system according to different conditions. The machine can realize stable and reliable welding of 1D and 2D curved welding, which has been currently applied in the field of rail transit, aerospace, defense industry, etc.

Technical Data

Model | AEE-FSW12×80/2 | ||

Welding Depth | (mm) | Aluminum1-16 | |

Working Table | (mm) | 4000*8000 | |

Passable Height | (mm) | 300-1300 | |

Passable Width | (mm) | 4600 | |

Stroke | X-axis | (mm) | 8000/25000 |

Y1/Y2-axis | (mm) | 3400 Dual-axis coverage | |

Z1/Z2-axis | (mm) | 1000 | |

C1/C2-axis | (°) | ±220 | |

A1/A2-axis | (°) | ±45 | |

Fast Moving Speed | X-axis | (mm/min) | 8000 |

Y1/Y2-axis | (mm/min) | 4000 | |

Z1/Z2-axis | (mm/min) | 4000 | |

C1/C2-axis | (rpm) | 5 | |

A1/A2-axis | (rpm) | 5 | |

Spindle Maximum Speed | (rpm) | 4000 | |

Machine Outline Dimension | (mm) | 13100*8900*6600 | |

Highlights

l Dynamic gantry

l Double beam and double gantry structure

l High precision and stable welding process

l High-quality spindle with hydraulic cooling system

l Meet the full coverage needs from thin sheet to thick plate

Features

l Automated tool changing system

l Force/ Position/ Torque / Temperature control

l Safety guarding system

l Remote assistance

l Data acquisition, visual identity, laser tracking and weld monitoring systems

Capacity

l Welding depth: 100 mm of single-side & 190 mm of double-side

l Welding material: Aluminum alloys & copper alloys

Application

Rail transit; electronics; defense industry